Basic Info.

Product Description

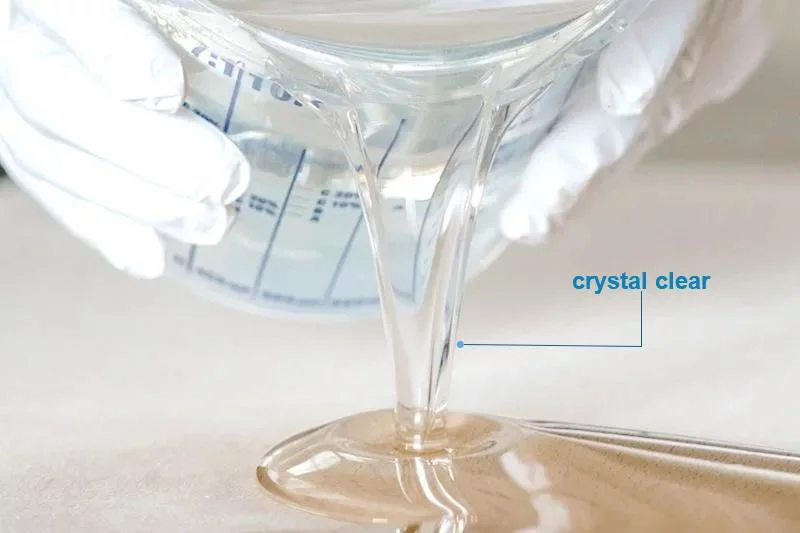

1.Kesswill clear and transparent epoxy resin AB glue made from basic pure resin and do well in adhesive.

2.Good at UV and yellow resistance,self leveling,without bubble,high brightness.

3.Can be cured at nomal temperature or by heating.

4.Clear,low viscosity,nature defoaming, super transprency and good performance after mixed.

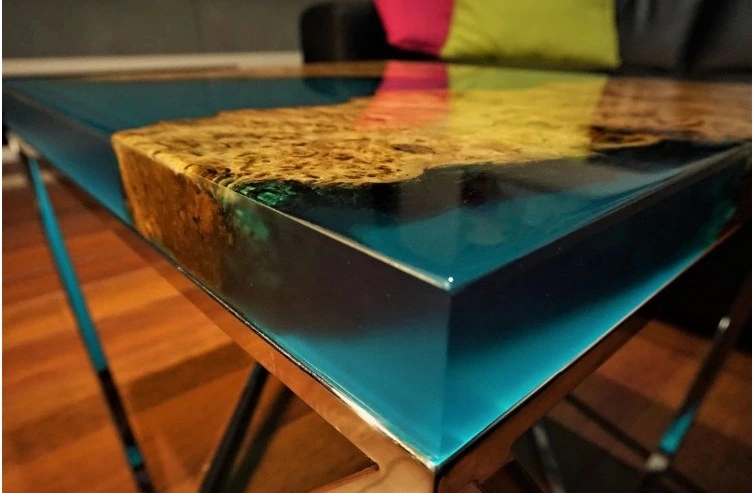

5.Can get any color you want by add pigments.

6.Easy to clean and repair.

7.No ripple,bright in surface,odourless,eco-friendly,nontoxic,waterproof and so on.

Properties before Hardening

| Part | 318A-7T | 312A-7T |

| Color | Transparent | Transparent |

| Specific gravity | 1.15 | 0.96 |

| Viscosity (25ºC) | 2000-4000CPS | 80 MAXCPS |

| Mixing ratio | A: B = 100:33(weight ratio) | A: B = 100:33(weight ratio) |

| Hardening conditions | 25 ºC×8H to 10H or 55ºC×1.5H (2 g) | 25 ºC×8H to 10H or 55ºC×1.5H (2 g) |

| Usable time | 25ºC×40min (100g) | 25ºC×40min (100g) |

Operation

1.Weigh A and B glue according to the given weight ratio into the prepared cleaned container, fully mixed the mixture again the container wall by clockwise, place it along for 3 to 5 minutes, and then it can be used.

2.Take the glue according to the usable time and dosage of mixture to avoid wasting. When the temperature is below 15 ºC, please heat A glue to 30 ºC first and then mix it to the B glue (A glue will be thicken in low temperature ); The glue must be sealed lid after use to avoid rejection caused by moisture absorption.

3.When the relative humidity is higher than 85%, the surface of the cured mixture will absorb moisture in the air, and form a layer of white mist in the surface, so when the relative humidity is higher than 85%, is not suitable for room temperature curing, suggest to use the heat curing.

5kgs per bottle; 20kgs per carton

20kgs per barrel

200kgs per barrel

FAQ