Basic Info.

Mould Cavity

Multi Cavity

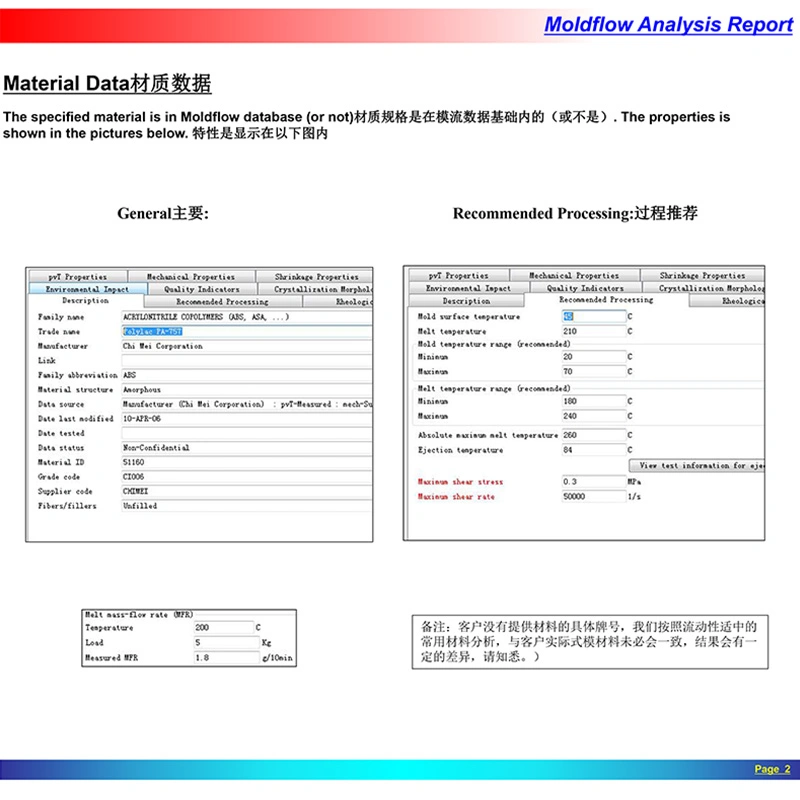

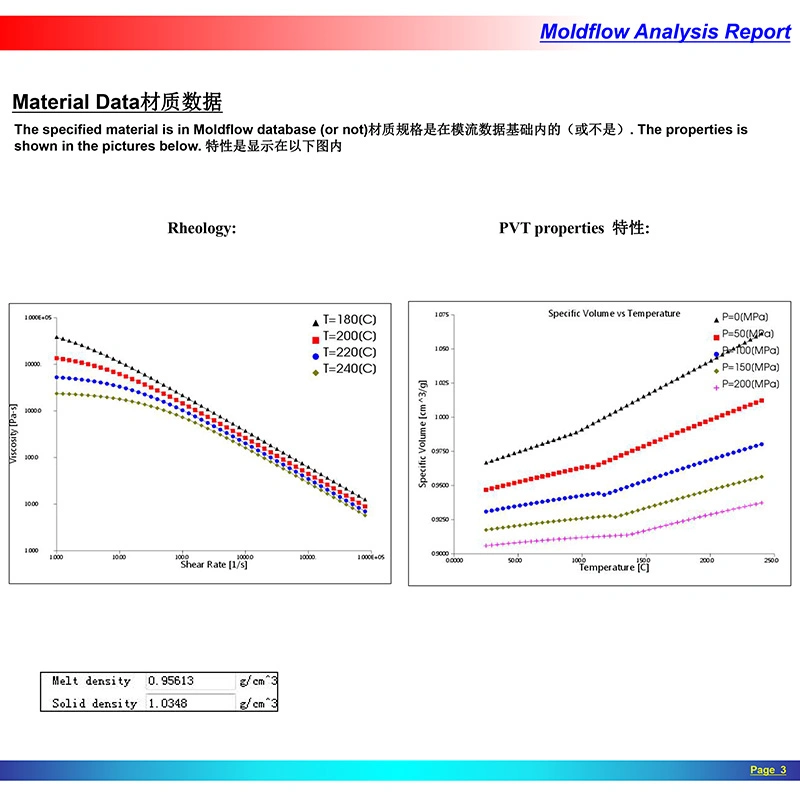

Plastic Material

ABS

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Runner

Hot Runner

Design Software

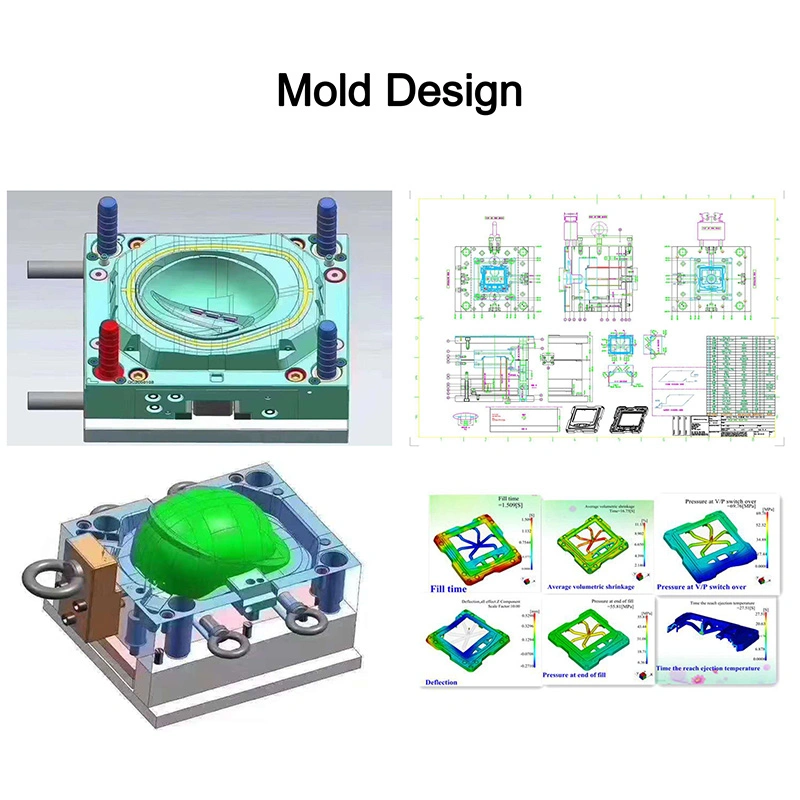

UG

Installation

Fixed

Certification

TS16949, CE, ISO

Standard

HASCO

Customized

Customized

After-sales Service

3 Years

Transport Package

Wood or Customized

Specification

Customized

Trademark

OEM

Origin

China

Production Capacity

600set/Years

Product Description

| Products Information | ||

| Product Name | Plastic Injection Mould | |

| Shaping Mode | Plastic Injection Mould | |

| Surface treatment | Polish. Etched. Texture | |

| Ejection System | Ejector pin | |

| Part Material | ABS | |

| Mold Standard | HASCO standard | |

| Packaging | According to customers' requirement | |

| Mould Steel | A plate | S50C |

| B plate | S50C | |

| Cavity Insert | S136 (HRC 45-50 ) | |

| Core Insert | S136 (HRC 45-50 ) | |

| Slider Insert | 2344 | |

| Ejector Plate | S50C | |

| Spare Parts | S50C | |

| Mould Description | Mould Gross Weight(KGS) | 965 |

| Mould Life Time(Shots) | 1,000,000 | |

| Mould Manufacturing Cycle | 35 days | |

| Surface Finish | Polishing | |

| Runner Description | Hot runner | |

| Ejection System | Eject blade | |

| Cycle Time(Second) | 55s | |

| Injection Gate Type | Side gate | |

| Mould Type | Plastic Injection Mold |

| Mould Material | P20/718/738/NAK80/S136 |

| Mould Base | HASCO,DME,MISUMI,JIS,LKM etc |

| Mould Runner | Cold Runner/ Hot Runner |

| Mould Gate | Slide Gate/Sub Gate/Pin- point Gate |

| Cavity | Single /Multi Cavity |

| Designing Software | UG/PROE/CAD/SOLIDWORKS |

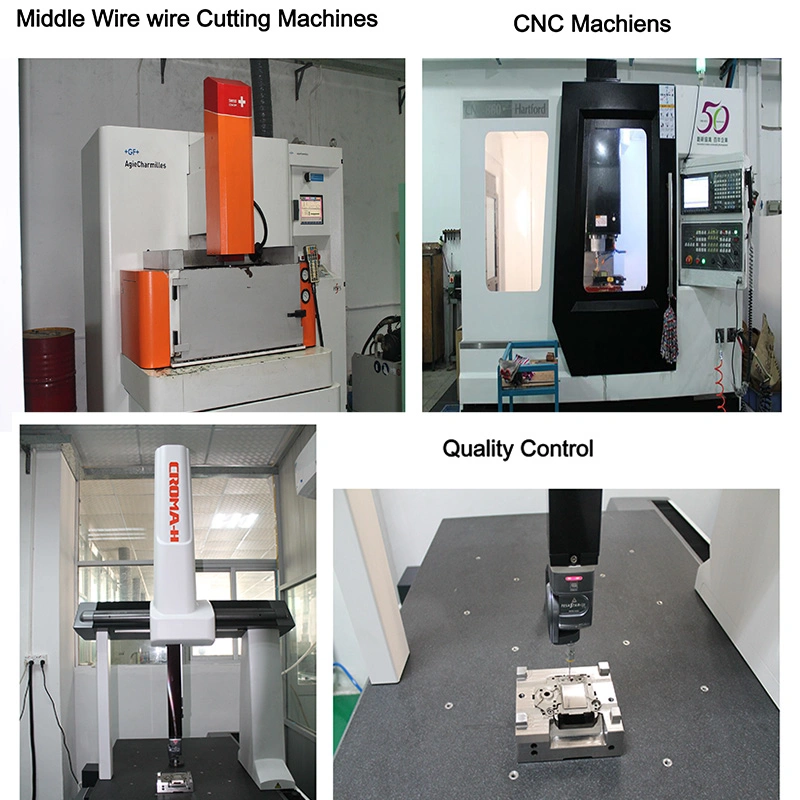

| Moulding equipment | CNC,Wire Cutting,Milling Machine,EDM |

| Raw-material | ABS,PP,PC,PA6,PA66,PVC,POM,PMMA,PS etc |

| Package way | Wooden pallet, carton |

| OEM/ODM | Welcome and please offer 2D/3D file or sample |

| Lead time | About 20 days |

POWERFULSKY MOULD Located in ShenZhen,near by HongKong.PowerfulSky Mould specializes in injection moulding production and injection mould making. In pursuit to provide our clients with economical solutions, our 9000 square meters facility offers a wide range of machinery, ranging from 60 Tons -1000 Tons precision injection moulding capacities, toatomized robotic arm sorting and packing production lines. As the development of the world economic integration, PowerfulSky Mould will spare no efforts in exploring under the principle of " Making your concept into reality". There is no job too small for us. Please enquire so we can help you find a solution.

In-House Design and Manufacturestanding at the forefront of injection moulding and tooling for more than 20 years, PowerfulSky Mould prides itself in our In-House Design and Manufacturing. We employ highly skilled and professional operators for our drilling, CNC, EDM, Proprietary Mirror EDM, Mould Polishing machines. PowerfulSky Mould passed ISO9001 and IATF16949 quality management system certification. As well as ROHS environmental protection system and SGS certification. SPC is widely used in product development design, mould making, products molding, painting, coating, silkscreen and assembly, to ensure our products in high quality and high finish standard.

Powefulsky Mould strives to produce high quality products and fast delivery times forall our clients by providing a complete service. From start to finish we offer Design,Prototyping, Mould making,production, packaging and shipping. Products covered by the industr ies of medical devices, beauty and care, household appliances, Netcom products and Auto and so on. PowerfulSky Mould's clients from all over the world as: USA, Europe, Brazil, Russia, Australia New Zealand and so on. We always believe technology is the primary productive force for the existence and development of the enterprises.