- Overview

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Product Description

| PLASTIC INJECTION PART BASIC INFORMATION | |

| Product Name | medical plastic injection molding parts |

| Surface Requirement | Texture EDM SPI Chrome Coating |

| Plastic Part Resin | thermoplastic/Thermosetting |

| Tolerance Request | UP to (±0.005mm) |

| Production Quantity | Up to 1 miliion |

| Part Size Range | Up to 1500mm |

| Multi Injection | Single/Double/multi color |

| Design Software | Data exchange: UG, PRO/E, SOLIDWORKS, CAITA, CAD, STP, X_T, IGS, PRT, DWG, DXF |

| Quality Assurance | Design Control, Steel Hardness Inspection Report, Steel Dimension Control Report, Mold Core and Cavity Dimension Inspection Report |

| PLASTIC INJECTION MOULD BASIC DESCRIPTION | |

| Injection System | Hot runner /Cold Runner |

| Cavitation | Single /Mutil Cavites |

| Ejector System | Pin/air Valve/Stripper plate |

| Steel Standard | ASSAB/FINKL/BOHLER/ Groditz/Buderus |

| Cooling | Baffles/Sprin Piple/3D printing water line |

| Standard Delivery | 40 days or 5 weeks |

| Standard Parts/Cylinders | DME/HASCO/PROGRESSIVE/MISUMI/Parker/HP/Merkle |

| Design Capability | DFM,Mould flow analysis,Product optimization, Full 2D & 3D mould design,Reverse engineering,Collaborative design with customer's idea |

| Documents / Reports Provided | Fully drawing,Weekly Processing Report, Steel Dimension report, Processing Report,Sample Dimension Report. |

Medical product and Cosmetics

Industrial designers typically focus on function, appearance, and ergonomics. ACE's design engineers add a vital

Criteria; designing for manufacturability. By using different Medical and Cosmetics tools and concepts such as

Mold flow analysis, prototyping, scientific molding analysis and automation consideration, ACE engineers can

Eliminate inefficiency or potential problems resulting in significant down-the-line savings for OEMs in the

Ramp up process. Our design and engineering staff are ready to make your medical product concepts a reality or

Re-engineer existing Products for improved quality and cost.

ACE is well versed in many manufacturing technologies critical to the Medical goods industry such as precision

Mold making and molding, high gloss molding, co-injection molding, and different surface finishing including pad

Printing and electroplating.

Our Services

ACE Molding Group is a privately owned company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception.Is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards.Our team of CAD designers will ensure that your imagination is incorporated into the actual product!If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!Our products include :

*Custom Plastic Injection Parts

*Multi-cavity plastic parts

*High Precision Molds

*Insert & over molding

*Double Short Molding

*Unscrewing Molding

*Gas-assisted Molding

*Die Casting Molding

*Prototype plastic parts and Low cycle plastic parts molding

*Gas Assist molding

*Elastomeric molding

*IML & IMD part production

*Thin wall plastic molding

*High temperature molding

*Foam Injection molding

Why Choose Us

1. We have our own design and development team and factory, with more than 14 years of product production experience. Familiar with and good at developing business with overseas market.

2. We can provide OEM/ODM services for all kinds of customers, and our professional support team will provide services for customers 24 hours a day.

3. We have a very strong quality control system to ensure the best quality of our products, the best service and competitive price.

4. Samples are always available for quality inspection and can be sent to you very quickly.

5. Design ability: design according to customer requirements.

6. We deliver goods on time and cooperate with customers sincerely.

Inspection Method

if customer needed, we can provide all these documentation for their reference.

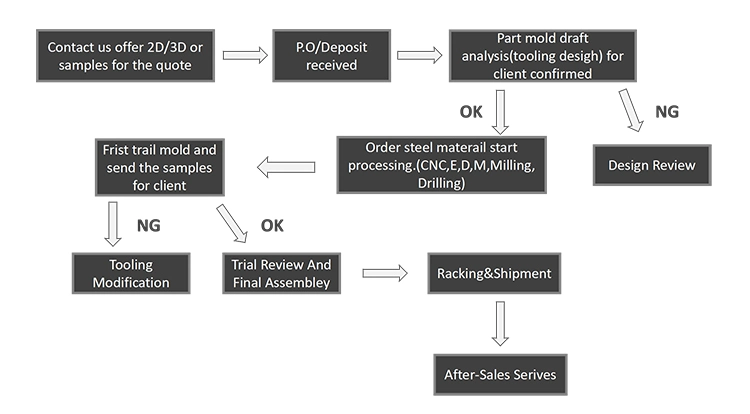

How To Order

Kindly contact or email us your inquiries or RFQs. One of our sales team would contact you asap and offer professional consultation on all your plastic molding needs and provide the best price that is suitable to your requirements.

Company Profile

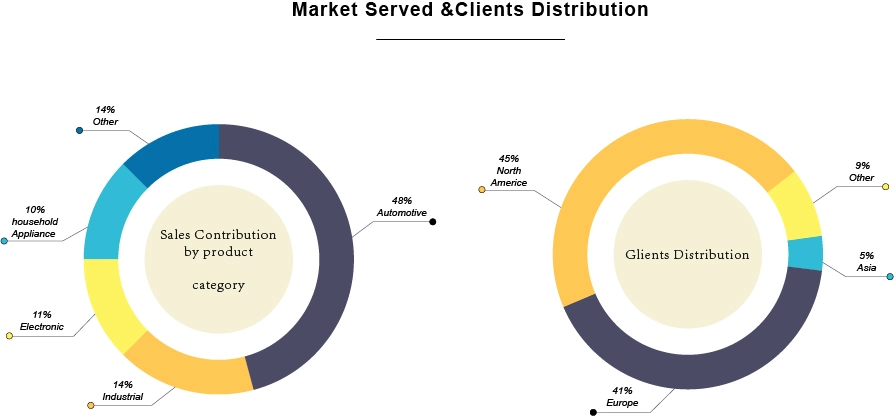

We are managed by a group of professionals with many years of experience in mould design, molding technology and quality control. Our clients are able to communicate with us freely in English, Japanese ,German and US, Since we build exclusively for the international market, mainly Europe, Japan North & South America, we have developed an excellent understanding of the technical and quality requirements needed.

* Plastic part: 0.01m

| ACE MOLD & MOULDING EQUIPMENT & PRESS LIST 2022 | |||||

| Department | Major Equipment | Name | Specification | Unit | Total |

| Mold Department | CNC Machining Center | ROEDERS RFM-800 Precision Centre Made in Germany | 36000/min | 2 | 15 |

| ROEDERS RXP-500 Precision Centre with Renishaw online inspection Made in Germany | 50000/min | 2 | |||

| ROEDERS RFM-600 Precision Centre with Renishaw online inspection Made in Germany | 42000/min | 2 | |||

| ROEDERS RFM-600 Precision Centre Made in Germany | 42000/min | 2 | |||

| KT-600II Precision Centre | 24000/min | 3 | |||

| Priminer V2013HS Size:2000*1300*800mm | 20000/min | 1 | |||

| FANUC α-D14MiA | 30000/min | 1 | |||

| Shenghong taiwan | 8500/min | 2 | |||

| Electric Discharge Machine(EDM) | SODICK EDM Machine | AD30L | 4 | 12 | |

| MAKINO | EDGE3 | 2 | |||

| EDGE2 | 2 | ||||

| Wintop | 350 | 2 | |||

| Wintop | DE -650 | 2 | |||

| Milling Machine | Milling machine | 16SS | 8 | 9 | |

| Mazak | Milling machine | QTN150 | 1 | ||

| Wire cut machine | Sodick ALN 600Gs | 0.002mm | 1 | 5 | |

| Sodick ALN 400Gs | 0.002mm | 1 | |||

| MV1200S | 0.005mm | 3 | |||

| Fitting machine | ShunXing | Max:100Ton | 1 | 1 | |

| Grind machine | Kent KGS-7132AH | Size:1000*350mm | 1 | 6 | |

| Xiangyu EM618 | Size:400*270*200mm | 5 | |||

| Drill Press Machine | Drill Press machine | Z3032X10 | 1 | 1 | |

| Molding Department | Plastic injection machine | Injection machine | Fanuc-CX250 | 10 | 31 |

| Kiaming 98T | 1 | ||||

| Kaiming128T | 2 | ||||

| Kaiming 168 T | 2 | ||||

| HaiTian 200T | 8 | ||||

| Taiwan 250T | 1 | ||||

| Toshiba 220T | 1 | ||||

| Kaiming 400T | 2 | ||||

| Kaiming 450T | 1 | ||||

| HaiTian 650T | 2 | ||||

| HaiTian 1300T | 1 | ||||

| Quality Department | Inspection machine | 2.5D Video Measuring System | VMS-2015F | 1 | 3 |

| Alberlink CMM | HR-150A | 2 | |||

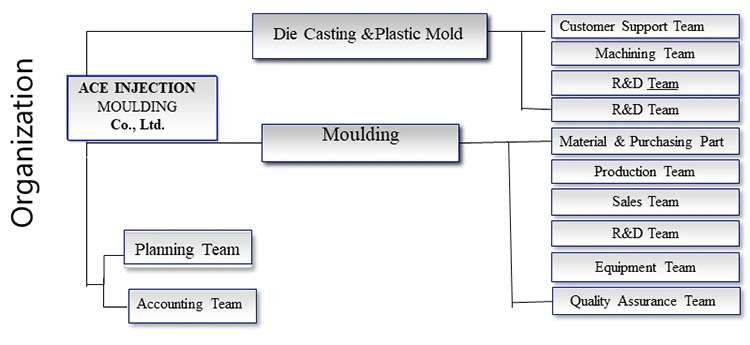

Organization

* 8 project engineers

* 60 tool makers

Our factory is under ISO standards & certification.This insures productivity and total control on quality.

Our standard packaging for plastic injection parts we use PP bag plus cardboard boxes or as per customer requirements. Our standard packaging for plastic injection mold is wooden pallets or wooden cases.

Our website lists some of our successful products, but please note that this is just one example on behalf of our products and services, so if you can't see the products you want, please contact us immediately.

We warmly welcome customers all over the world and are looking forward to establishing a steady and long-term business relationship with you .

Q: What services do you provide?

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.