- Overview

- Product Description

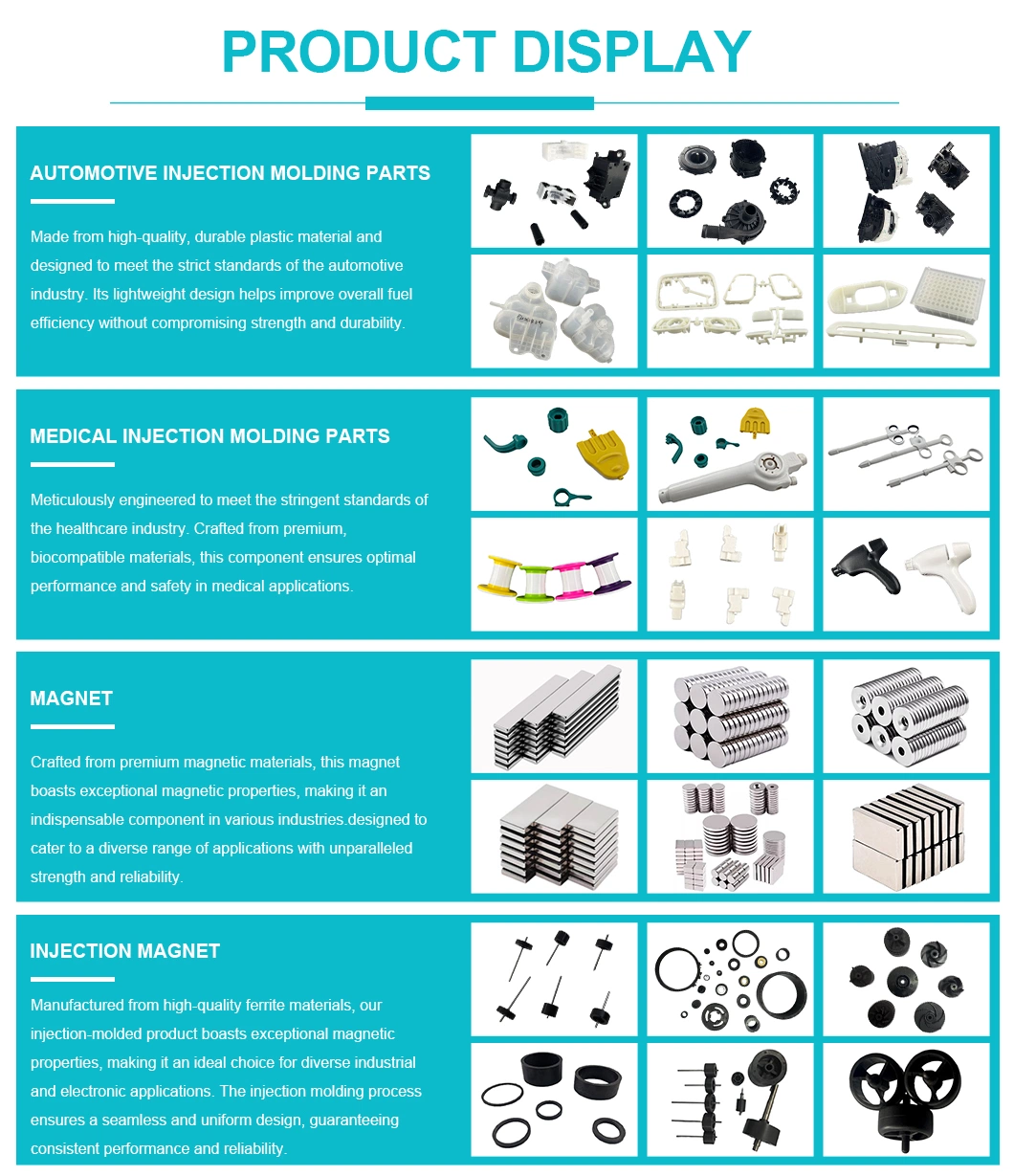

- Product display

- Our Advantages

- Company Profile

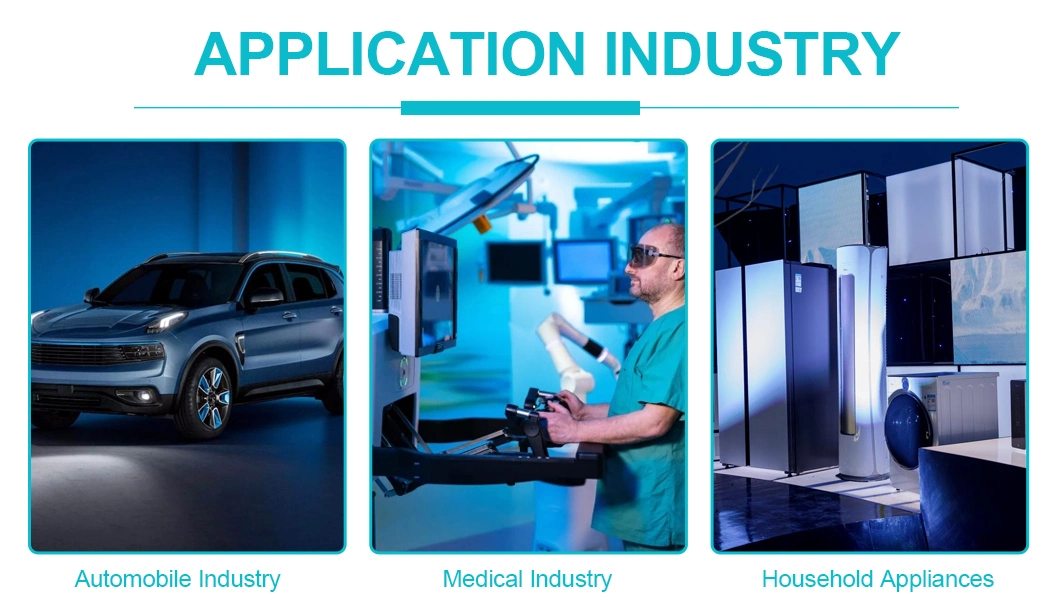

- Application

- Partner

- Certifications

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Automotive Injection Molding Parts Description

Introducing our premium automotive plastic components, designed to enhance the performance and aesthetics of your vehicles. Crafted from high-quality, durable plastic materials, these components are engineered to meet the rigorous standards of the automotive industry. Their lightweight design contributes to overall fuel efficiency without compromising on strength and durability.

| Parameter | Description |

| Product Name | Customized Injection Molded Automotive Plastic Parts |

| Product Type | Automotive plastic parts |

| Applicable Models | Specific models or widely applicable to multiple models |

| Material | Polypropylene (PP), Polycarbonate (PC), Polystyrene (PS), Magnetic material(PA,PA66,PPS),etc. |

| Dimensions | Length, width, height, etc. |

| Weight | Unit: grams |

| Color | According to customer requirements or standard colors |

| Structural Design | Detailed description of the part's structure, features, and connection methods |

| Surface Treatment | Sanding, painting, silk-screen printing, etc. |

| Heat Resistance | Maximum temperature withstand capacity |

| Chemical Resistance | Resistance to oil, solvents, and chemicals |

| Wear Resistance | Ability to resist scratches and wear |

| Impact Resistance | Ability to withstand impact and vibration |

| Environmental Adaptability | Weather resistance, UV resistance, and corrosion resistance |

| Dimensional Tolerance | Permissible range of dimensional deviations |

| Production Process | Injection molding |

| Production Batch | Estimated production quantity |

| Quality Standards | Compliance with quality standards and certification requirements |

| Delivery Time | Estimated product delivery time |

| Packaging | Packaging type and specifications |

| Documentation and Certification | Product specifications, test reports, certification documents |

| Remarks | Any additional information or special requirements |

Hengke Molding Technology Co., Ltd. is a wholly-owned subsidiary of Weidekang Group, established in 2021. The company's headquarters is located in the private industrial park of Wujin Economic Development Zone in Changzhou City, Jiangsu Province, China. Specifically, it is situated in Area D, at the northwest intersection of Changtang Road and Changting Road.

Hengke Molding Technology is an innovative technology company specializing in the research, development, manufacturing, and sales of plastic products, magnetic products, molds, and high-end molded products. The company is dedicated to providing customers with a wide range of mold products that are diverse in variety, superior in quality, and competitively priced.

With years of development and accumulation, the company has established a well-known brand in the industry with a customer-centric approach. Hengke Molding Technology places quality compliance as a protective shield, tackles challenges through innovation, and overcomes difficulties through scientific management.

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Whyshould I choose your products?

A2. Our products are high quality and low price.

Q3. The logo and the color can be customized?

A3.Yes, we welcome you to sample custom

Q4. Any other good service your company can provide?

A4. Yes,we can provide good after-saleand fast delivery