Basic Info.

Packaging & Delivery

Product Description

Features

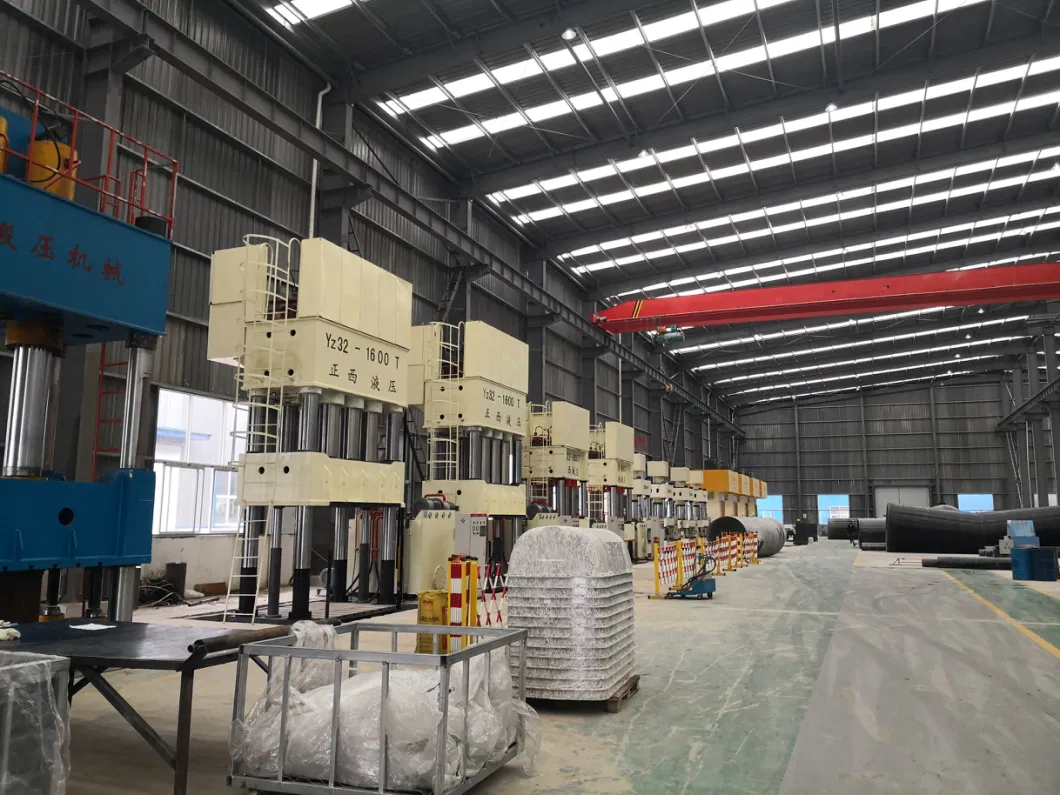

1. The frame is heavy-duty as well as compact and it assures precise results. It is made of high quality mild steel and it has undergone systematicmechanical processes.

2. Electric welding of high precision

3. Usage of high-tech boring machines for extreme precision parts

4. The composite series has been designed for applications in which structural rigidity and lexibility in terms of production are the particular rerogatives required. Machines with several actions from the top or bottom or pecial solutions enable complex shapes and large dimensions to be achieved in a number of different industries.

5. It is convenient to clean and change oil.

6. Factory full set of solution

Parameters

| Model | Unit | Yz27-200T | Yz27-315T | Yz27-500T | Yz27-650T | Yz27-800T | Yz27-1000T | Yz27-1250T | |

| Nominal Force | KN | 2000 | 3150 | 5000 | 6500 | 8000 | 10000 | 12500 | |

| Max working pressure of liquid | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| Plate press | KN | 630 | 1000 | 2000 | 2500 | 3150 | 4000 | 5000 | |

| Max. Open height | mm | 1200 | 1500 | 1600 | 1700 | 2000 | 2300 | 2500 | |

| Stroke | mm | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1500 | |

| Plate stroke | mm | 250 | 300 | 350 | 350 | 400 | 400 | 500 | |

| Slide speed | Down | mm/s | 80 | 120 | 120 | 200 | 300 | 270 | 300 |

| Pressing | mm/s | 10~20 | 10~25 | 14~35 | 10~35 | 10~35 | 10~35 | 15-30 | |

| Return | mm/s | 80 | 130 | 115 | 150 | 150 | 270 | 200 | |

| Table size | Left-right | mm | 800 | 1600 | 1800 | 2400 | 3000 | 3600 | 4600 |

| Front-back | mm | 800 | 1200 | 1600 | 1800 | 2000 | 2400 | 2400 | |

| Plate size | Left-right | mm | 600 | 1200 | 1400 | 1800 | 2200 | 2600 | 3600 |

| Front-back | mm | 550 | 800 | 1100 | 1200 | 1300 | 1500 | 1500 | |

| Motor power | KW | 22 | 44 | 60 | 74 | 90 | 110 | 190 | |

| Type | Four-column | Four-column | Four-column | Four-column | Frame | Frame | Frame | ||

Application

AFTER-SALE

1. Personnel training

Free training for about one week.

2. After-sale service

One year warranty. During warranty period, free maintenance service can be provided. (except man-made faults or damages arising from irresistible natural factors)

3. Installation

Customers need to pay the commission to our proffessional engineer, and travel expense is on foreign customer. (Including round ticket and accommodation cost)

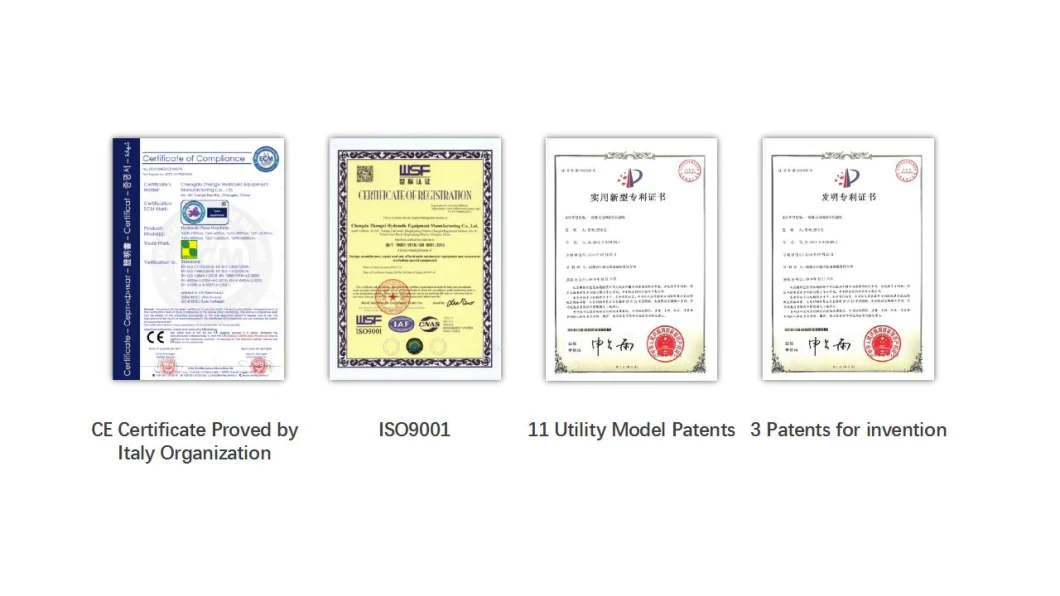

Our company is an ISO 9001 certified Company, and as an approved supplier for the automotive sector, has also received the CE certificates.