- Overview

- Product Description

- Company Profile

- FAQ

Basic Info.

Product Description

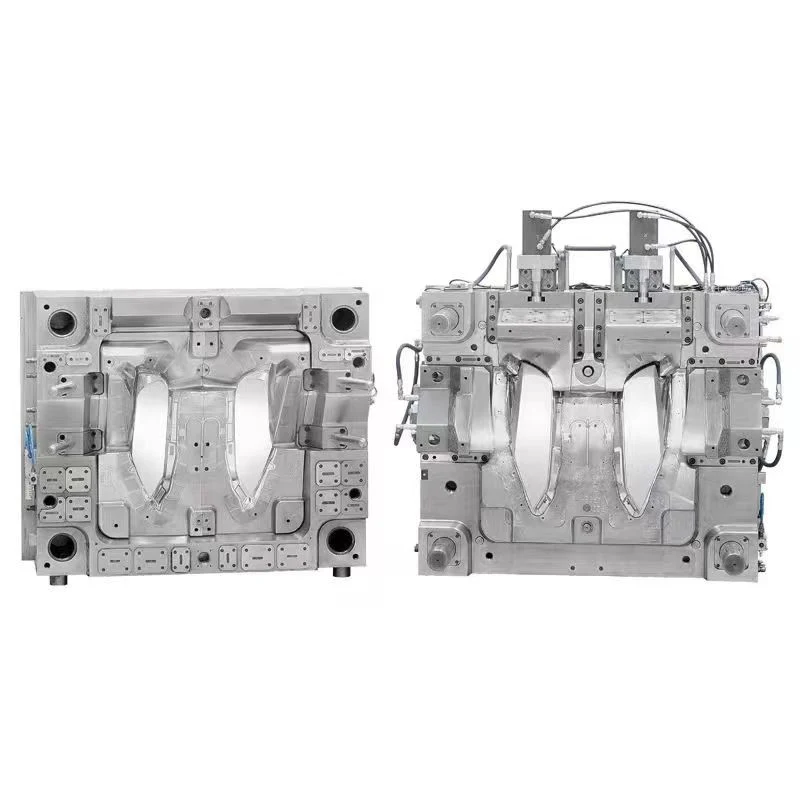

| Name | Plastic Injecition Mold |

| Mould core | P20,NAK80,SKD11,S316,S50C,S45C,718H,718 or customers' appointed |

| Mould base | LKM, HASCO, DME or upon customer's requirement |

| Type of plastic mold | 3-plate mold,2-plate mold |

| Cavity | Single/Multi 1*1,1+1,1*2,1+1+1,etc |

| Mode Gate | Fan gate,Sub gate,Pin Point gate,Valve |

| Ejection system | Stripper plate,Lifter,Push Bar,Ejection Pin etc |

| Runner | Hot/cold type |

| Plastic material | HDPE, PP, nylon, PEEK, LDPE, ABS, styrene, acrylic, acetal, PE, PTFE, PEI, and PES |

| Mould life | 300,000-1,000,000 shots |

| Lead time | 15-35days after deposit received |

| Specification | Follow the 3D final drawing |

| Packaging details | covering with film for anti rust and packed with wooden Case |

Hintsteiner Plastic Technology Co., Ltd specializes in producing high-quality plastic injection tooling for baluster cement molds. Our molds are perfect for creating concrete balusters, and we also offer a wide range of other plastic molds for various applications, such as coffee cups, chairs, toothbrushes, automotive lamps, EPP products, thin wall items, and more. Contact us for affordable prices and top-notch plastic injection molding parts.

| Product Material | ABS,AS,PP,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc |

| Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

| MOQ | 500 PCS |

| Packaging details | Carton box or wooden Case upon product weight and customer's requirements. |

| Shipping | By sea or by air as customer requirement |

| Typical Used For | Housings, containers, caps, fittings,including as below Power-tool housing, Disposable razors, Electrical Switches,Crates/Recycling boxes Automotive dash boards,Television Cabinets,Drug Inhalation Units,Automotive bumpers, Wheelie bins ,Syringes,Telephone handsets ,Washing-up bowls,DVDs, Bottle Lids/closures,Battery Casings |

| Range of markets | industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter, healthcare, telecommunications, mechanical, water treatment, appliance, recreation, lawn and garden, educational, oil and gas, government, construction, plumbing, surveillance, pumps, marine, motors, gears, RFID tags, electronics, and fasteners. |

Hintsteiner Plastic Technology Co., Ltd

Welcome to Hintsteiner Plastic Technology Co., Ltd

Located in Guangdong, the Mould Hometown of China, Hintsteiner Plastic Technology Co., Ltd specializes in manufacturing high-quality plastic moulds. Our extensive range includes bumper moulds, auto parts moulds, commodity moulds, pallet moulds, trash bin moulds, waste bin moulds, home appliance moulds, crate moulds, bucket moulds, plastic containers moulds, pipe fitting moulds, pet preform moulds, costing moulds, and stamping die moulds.

With over 15 years of experience, our team of technical personnel and designers is dedicated to providing the best service and delivering top-notch moulds. We have earned a good reputation both domestically and internationally, with more than 95% of our moulds being sold to Europe, North America, South America, Asia, and over 30 other countries and regions.

At Hintsteiner Plastic Technology Co., Ltd, we constantly strive to update our technology and improve our competitiveness. As a modern management enterprise, we leverage CAD/CAE/CAM technology, CAD/CAM graphics workstations, and graphics drawing instruments and equipment. Additionally, we utilize C-mould software and mould analysis of reverse engineering design software system to quickly adapt to our customers' requirements.

Our moulds are known for their high precision, long life, short production period and delivery time, reasonable price, and satisfactory service. We take pride in the popularity and credit our products have gained.

We look forward to cooperating with both new and old customers to create a beautiful future together.