Basic Info.

Model NO.

YS135

Warranty

12 Months

Customized

Customized

Condition

New

Size

30/32/38/48/64

Cavity

2/4/8/12/16/18/20/24/28/32/36/48

Mould Matieral

P20\S136\2316\#45\718/ Copper

Polish

High Polish

Process

Hot/Cold

Gate

Pin Point/Edge Gate

Transport Package

Wooden Package

Specification

SGS

Trademark

Yongsheng

Origin

China

HS Code

8480719090

Production Capacity

500sets/Year

Product Description

1.ADVANTAGE:

1.Saving 10%-30% cost than others.

2. Direct factory price

3. Life:3, 000, 000 time

4.2D and 3D provided

5. Quick T1 time: 25-40 days

6.More than 15 years experience

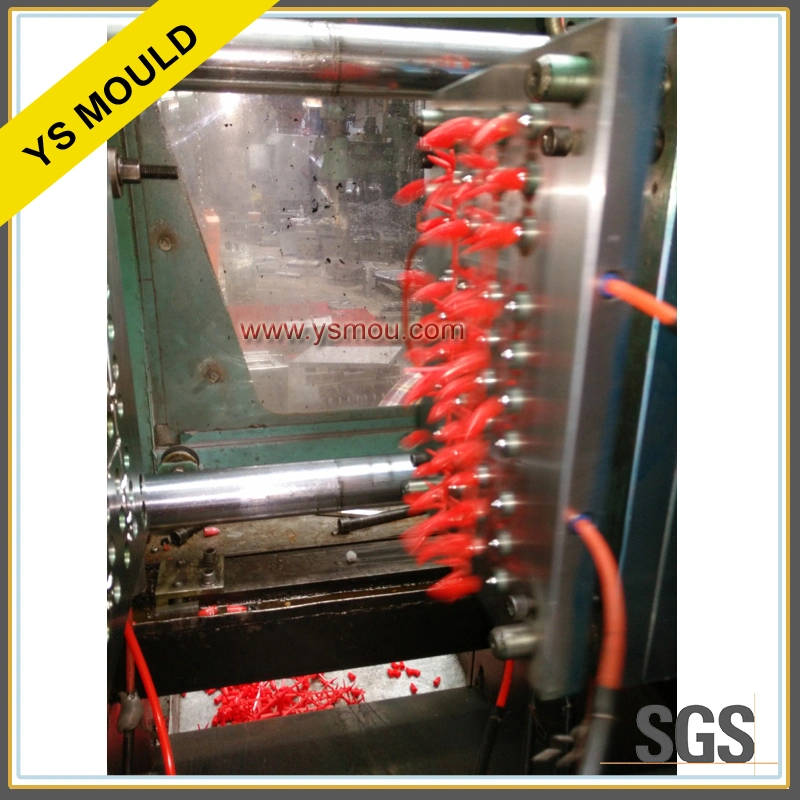

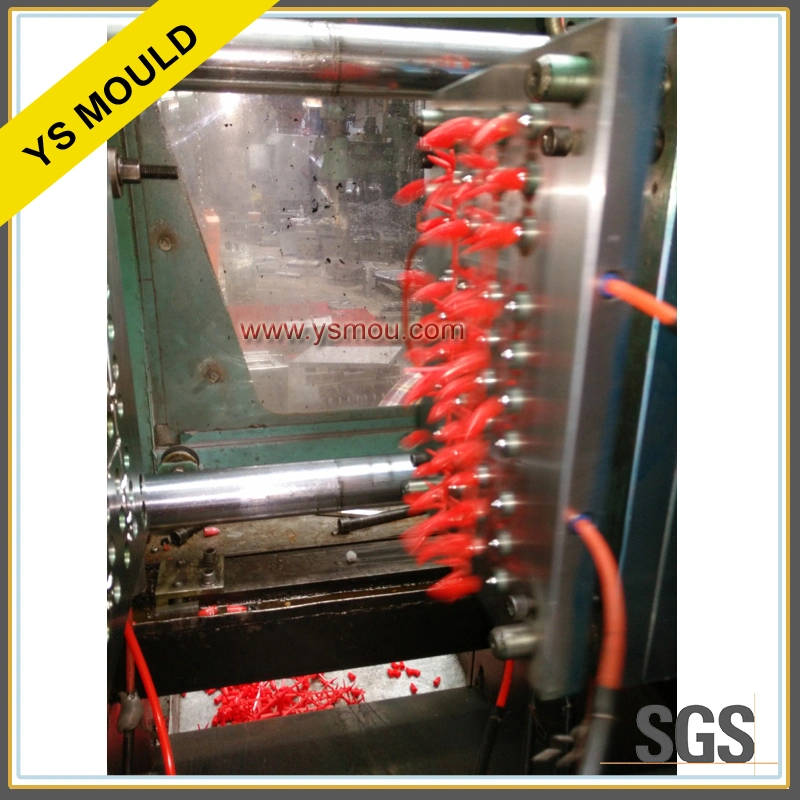

2.PICTURE:

3.MOULD DESCRIPTION:

1.Cavity:1-72

2.Mould base material :P20 , 45# , 4CR13 , .ECT

3.Core&Cavity mat erial : S136, 718, P20 , 2378 , 2316 , 4CR13,P20 .ECT

4.Runner: Cold /Hot (LOCAL BRAND,HASCO,YUDO,HUSKY .ETC)

5.Life time:3,000,000 shots

6.Quick T1 time:25-40 days

7.Package:wooden case

4.MOULD MANUFACTURE PROCESS:

Cap Mould : grinding → fly-cutter →CNC Milling→ drilling → lathe → boring lathe → electric pulse →fine fly-cutter →polish→ electroplate → install

Preform Mould: grinding → drilling → lathe → boring lathe →fine fly-cutter →polish→ electroplate → install

Need vale ,itself-locking :new advanced needle vale gate system.each cavity is self-lock independently to ensure low decent ration of product.

The excellent hot runner design assures uniform heating and greatlyimproves the quality of plastic products

5.AFTER SALE SERVICE:

Any mould problem,we will provide free maintenance service

6. FLOW CHART

7.CONTACT ME :

.

1.Saving 10%-30% cost than others.

2. Direct factory price

3. Life:3, 000, 000 time

4.2D and 3D provided

5. Quick T1 time: 25-40 days

6.More than 15 years experience

2.PICTURE:

3.MOULD DESCRIPTION:

1.Cavity:1-72

2.Mould base material :P20 , 45# , 4CR13 , .ECT

3.Core&Cavity mat erial : S136, 718, P20 , 2378 , 2316 , 4CR13,P20 .ECT

4.Runner: Cold /Hot (LOCAL BRAND,HASCO,YUDO,HUSKY .ETC)

5.Life time:3,000,000 shots

6.Quick T1 time:25-40 days

7.Package:wooden case

4.MOULD MANUFACTURE PROCESS:

Cap Mould : grinding → fly-cutter →CNC Milling→ drilling → lathe → boring lathe → electric pulse →fine fly-cutter →polish→ electroplate → install

Preform Mould: grinding → drilling → lathe → boring lathe →fine fly-cutter →polish→ electroplate → install

Need vale ,itself-locking :new advanced needle vale gate system.each cavity is self-lock independently to ensure low decent ration of product.

The excellent hot runner design assures uniform heating and greatlyimproves the quality of plastic products

5.AFTER SALE SERVICE:

Any mould problem,we will provide free maintenance service

6. FLOW CHART

| 1 | Sample or 2D,3D drawing from customer |

| 2 | Bulid 2D,3D drawing |

| 3 | CAD mould design |

| 4 | Send drawing to customer to confirm |

| 5 | Parts inspection/CNC machining/EDN machining |

| 6 | Mould assembly |

| 7 | Mould test |

| 8 | Send sample to confiom |

| 9 | Dilver the mould |

7.CONTACT ME :

.