Basic Info.

Model NO.

MG-ER84D

Brand

Mgcow

Appearance

Liquid, Clear

Classification

Room Curing

Characteristic

Waterproof

Transport Package

5kg/Drum, 20kg/Drum, 2000kg/Drum

Trademark

MGCOW

Origin

China

Production Capacity

10tons/Day

Product Description

Description of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood:

It is a crystal-clear, low-viscosity epoxy resin and is produced and distributed exclusively in premium quality. It is ideal for almost any application. For example: in the jewelery sector, table manufacturing, for river tables for floors, ponds,aquarium and terrarium construction, as well as for boat, ship and aircraft construction.

It is an epoxy resin adhesive cured at room temperature and low temperature. It has good fluidity, natural defoaming, yellowing resistance and odorless.Dedicated to river tables, wood and resin combined art tables, crafts, accessories.

1.Non-toxic

2. 100% Solid

3. VOc Free

4.Solvent Free

5.Crystal Clear

6.Epoxy Resin and hardener,mix ratio of 2:1

7.Thick Pour to 2"-4"

It is potted need to be kept dry and clean; Please check the A agent first, observe whether there is any sedimentation, and stir the A agent evenly;

According to the ratio of the ratio, and the weighing is accurate, please remember that the ratio is the weight ratio rather than the volume ratio.

After mixing the A and B agents, stir well to avoid incomplete curing.

After mixing evenly, please fill the glue in time, and try to use the mixed glue in the available time;

Keep the environment clean during the curing process to prevent impurities or dust from falling onto the surface of the uncured glue

Application of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood :

Perfect for River Tables, Deep Cast Arts & Crafts, Woodworking, and much more

Warm Notes of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood :

1. Proportion: A: B = 3:1 (weight ratio)

2. Available time: 25°C×20 minutes (10kg mixing amount)

3. Curing condition, dry at room temperature for 24 hours

4.After demoulding, it takes 48 hours to react to complete hardness to achieve grinding hardness.

5.Medium hardness: shore D >84.

6.Potting thickness must not exceed 10CM. If it exceeds the limit thickness, the product will be deteriorated due to heat and high temperature. Because the product will produce heat on the open surface of the mold during the curing process.

7.Glue contacting with the air surface should be arranged in moderation.

8.The mixing amount should not be less than 3KG.Too small mixing amount will result in prolonged curing time of the product.

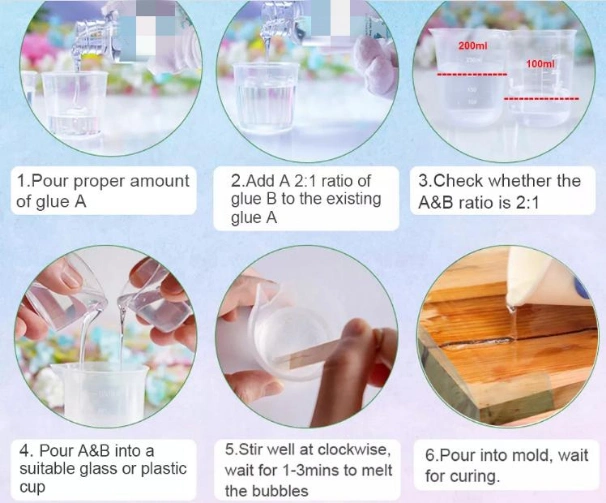

Using instruction of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood :

Features of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood:

FAQ of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood :

1.Q: What's the best way to mix this?

A: You'll want to make sure that you have 3 parts base resin and 1 part curing agent measured precisely, by volume. Pour each into your mixing bucket, and we recommend mixing by hand for at least 3 minutes and between 3-5 minutes or until it is fully mixed. Be careful to scrape the sides while mixing, but when pouring, do not scrape the sides. This can impart unmixed material that may cling to the side and has not been incorporated. Don't worry about any bubbles in the mixture, they will all work themselves out.

2.Q: How long does it take to cure, and what temperatures can I pourthis in?

A: Our optimum environment temperature range is 72° - 84°F (in a clean, temperature controlled environment. In that temperature range, it will begin to gel in 20-30 minutes, and cure rock hard within 24 hours.Temperatures under 70° will slow the curing process even more, and the closer you get to 60° the curing process will stop. Above 85°, it will begin to accelerate curing, leading to cracking, shrinking and other negative results.

3.Q: When Can I Demould?

A: Our optimum environment temperature range is 72° - 84°F in a clean temperature controlled environment. In that temperature range, you can demould between 18 and 24 hours, and its optimal workability will be at 24-30 hours. At 30 hours it will sand and plane as easy as wood!

Packing and Delivery of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood :

5kg/drum, 20kg/drum, 200kg/drum

Company information:

It is a crystal-clear, low-viscosity epoxy resin and is produced and distributed exclusively in premium quality. It is ideal for almost any application. For example: in the jewelery sector, table manufacturing, for river tables for floors, ponds,aquarium and terrarium construction, as well as for boat, ship and aircraft construction.

It is an epoxy resin adhesive cured at room temperature and low temperature. It has good fluidity, natural defoaming, yellowing resistance and odorless.Dedicated to river tables, wood and resin combined art tables, crafts, accessories.

1.Non-toxic

2. 100% Solid

3. VOc Free

4.Solvent Free

5.Crystal Clear

6.Epoxy Resin and hardener,mix ratio of 2:1

7.Thick Pour to 2"-4"

It is potted need to be kept dry and clean; Please check the A agent first, observe whether there is any sedimentation, and stir the A agent evenly;

According to the ratio of the ratio, and the weighing is accurate, please remember that the ratio is the weight ratio rather than the volume ratio.

After mixing the A and B agents, stir well to avoid incomplete curing.

After mixing evenly, please fill the glue in time, and try to use the mixed glue in the available time;

Keep the environment clean during the curing process to prevent impurities or dust from falling onto the surface of the uncured glue

Application of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood :

Perfect for River Tables, Deep Cast Arts & Crafts, Woodworking, and much more

Warm Notes of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood :

1. Proportion: A: B = 3:1 (weight ratio)

2. Available time: 25°C×20 minutes (10kg mixing amount)

3. Curing condition, dry at room temperature for 24 hours

4.After demoulding, it takes 48 hours to react to complete hardness to achieve grinding hardness.

5.Medium hardness: shore D >84.

6.Potting thickness must not exceed 10CM. If it exceeds the limit thickness, the product will be deteriorated due to heat and high temperature. Because the product will produce heat on the open surface of the mold during the curing process.

7.Glue contacting with the air surface should be arranged in moderation.

8.The mixing amount should not be less than 3KG.Too small mixing amount will result in prolonged curing time of the product.

Using instruction of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood :

Features of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood:

FAQ of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood :

1.Q: What's the best way to mix this?

A: You'll want to make sure that you have 3 parts base resin and 1 part curing agent measured precisely, by volume. Pour each into your mixing bucket, and we recommend mixing by hand for at least 3 minutes and between 3-5 minutes or until it is fully mixed. Be careful to scrape the sides while mixing, but when pouring, do not scrape the sides. This can impart unmixed material that may cling to the side and has not been incorporated. Don't worry about any bubbles in the mixture, they will all work themselves out.

2.Q: How long does it take to cure, and what temperatures can I pourthis in?

A: Our optimum environment temperature range is 72° - 84°F (in a clean, temperature controlled environment. In that temperature range, it will begin to gel in 20-30 minutes, and cure rock hard within 24 hours.Temperatures under 70° will slow the curing process even more, and the closer you get to 60° the curing process will stop. Above 85°, it will begin to accelerate curing, leading to cracking, shrinking and other negative results.

3.Q: When Can I Demould?

A: Our optimum environment temperature range is 72° - 84°F in a clean temperature controlled environment. In that temperature range, you can demould between 18 and 24 hours, and its optimal workability will be at 24-30 hours. At 30 hours it will sand and plane as easy as wood!

Packing and Delivery of 2-Part Crystal Clear Thick Pour Epoxy Resin for Art Casting River Tables Live Edge Slabs Silicone Molds Wood :

5kg/drum, 20kg/drum, 200kg/drum

Company information: