Basic Info.

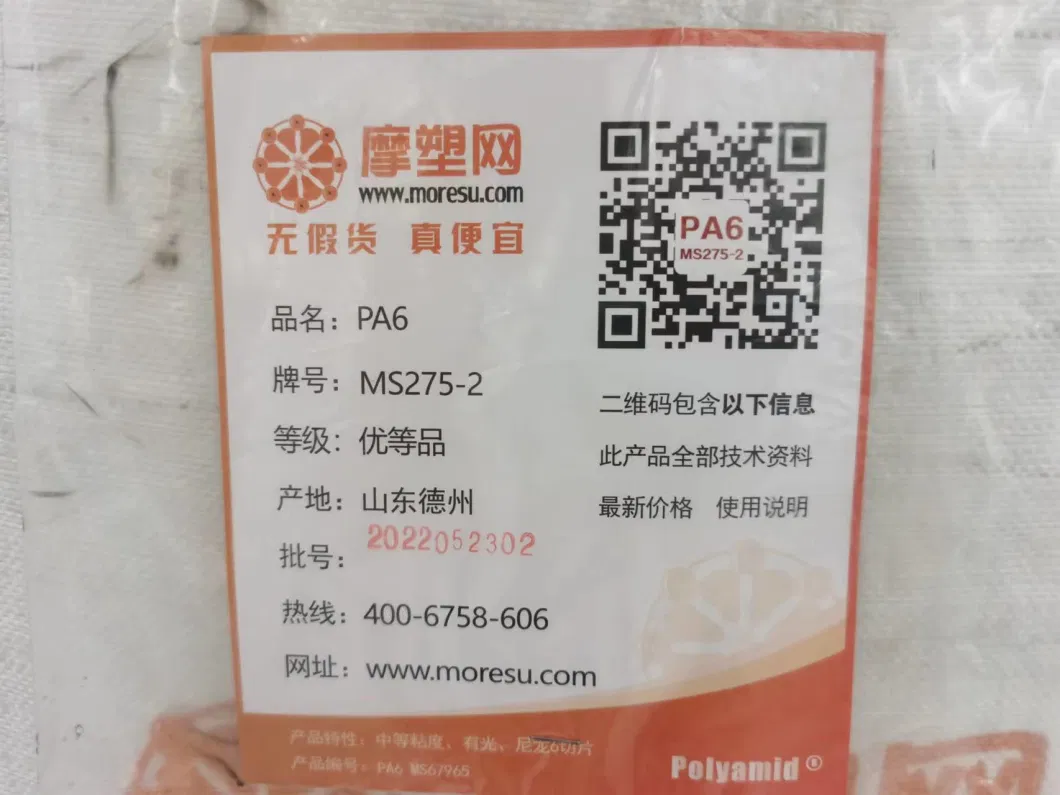

Model NO.

MS275

Plastic Forming Method

Injection

Color

Oyster White

Transport Package

PP Woven Bag

Specification

800Kg

Trademark

moresu

Origin

China

HS Code

390810

Production Capacity

50000 Tons/Year

Product Description

Basic Information:

Name: Nylon 6, PA6, Polyamide 6

Category: pure resin, resin without additives, Model: MS275

Brand: moresu

Quality level: excellent product

A country of origin: China

Product Description:

This is a polyamide 6 and nylon 6 product from China; the product is a pure resin raw material, no other additives are added, and you can add the ingredients you want to achieve the product performance you want. Jiangsu Plastic Union Technology Co., Ltd. distributes this product. The raw materials can be added with glass fiber, carbon fiber, glass fiber microbeads, mineral powder, etc. to increase the strength, and used for the production of functional parts, such as the shell of garden tools, the handle of electric tools,Bearing brackets, rolling wheels, motor skeletons, automotive connectors, oil pipes

Chemical physical properties:

The chemical and physical properties of Nylon-6 are very similar to those of Nylon 66, however, it has a lower melting point and a wide process temperature range. It has better impact and dissolution resistance than nylon 66 plastic, but is also more hygroscopic. Because many quality characteristics of plastic parts are affected by hygroscopicity, it is important to take this into account when designing products using nylon 6. In order to improve the mechanical properties of nylon 6, various modifiers are often added. Glass is the most common additive, and sometimes synthetic rubbers such as EPDM and SBR are added to improve impact resistance. For products without additives, the shrinkage of nylon 6 plastic material is between 1% and 1.5%. Adding glass fiber additives can reduce the shrinkage to 0.3% (but slightly higher in the direction perpendicular to the process). The shrinkage of molding assembly is mainly affected by the crystallinity and hygroscopicity of the material. Actual shrinkage is also a function of part design, wall thickness and other process parameters. Nylon 6 injection drying treatment Since nylon 6 easily absorbs moisture, special attention should be paid to the drying before processing. If the material is supplied in waterproof packaging, the container should be kept tightly closed. If the humidity is greater than 0.2%, it is recommended to dry in hot air above 80C for 16 hours. If the material has been exposed to air for more than 8 hours, vacuum drying at 105C for more than 8 hours is recommended. Nylon 6 injection molding process parameters Melt temperature: 240-250°C, 250-280°C for reinforced varieties.

Pre-drying: drying at 90°C for 4 hours, except for feeding directly from the charging container; nylon has water absorption and should be stored in a moisture-proof container and a closed hopper; water content exceeding 0.25% will cause molding changes .

Recovery rate: 10% recycled material can be added.

Shrinkage rate: 0.7%-2.0%; or adding 30% glass fiber, the shrinkage rate is 0.3%-0.8%; if the provided temperature exceeds 60ºC, the product should be gradually cooled; gradual cooling can reduce the shrinkage after molding. That is, the product shows better dimensional stability and small internal stress; it is recommended to use the steam method; nylon plastic products can be checked for stress by melting the flux.

Name: Nylon 6, PA6, Polyamide 6

Category: pure resin, resin without additives, Model: MS275

Brand: moresu

Quality level: excellent product

A country of origin: China

Product Description:

This is a polyamide 6 and nylon 6 product from China; the product is a pure resin raw material, no other additives are added, and you can add the ingredients you want to achieve the product performance you want. Jiangsu Plastic Union Technology Co., Ltd. distributes this product. The raw materials can be added with glass fiber, carbon fiber, glass fiber microbeads, mineral powder, etc. to increase the strength, and used for the production of functional parts, such as the shell of garden tools, the handle of electric tools,Bearing brackets, rolling wheels, motor skeletons, automotive connectors, oil pipes

Chemical physical properties:

The chemical and physical properties of Nylon-6 are very similar to those of Nylon 66, however, it has a lower melting point and a wide process temperature range. It has better impact and dissolution resistance than nylon 66 plastic, but is also more hygroscopic. Because many quality characteristics of plastic parts are affected by hygroscopicity, it is important to take this into account when designing products using nylon 6. In order to improve the mechanical properties of nylon 6, various modifiers are often added. Glass is the most common additive, and sometimes synthetic rubbers such as EPDM and SBR are added to improve impact resistance. For products without additives, the shrinkage of nylon 6 plastic material is between 1% and 1.5%. Adding glass fiber additives can reduce the shrinkage to 0.3% (but slightly higher in the direction perpendicular to the process). The shrinkage of molding assembly is mainly affected by the crystallinity and hygroscopicity of the material. Actual shrinkage is also a function of part design, wall thickness and other process parameters. Nylon 6 injection drying treatment Since nylon 6 easily absorbs moisture, special attention should be paid to the drying before processing. If the material is supplied in waterproof packaging, the container should be kept tightly closed. If the humidity is greater than 0.2%, it is recommended to dry in hot air above 80C for 16 hours. If the material has been exposed to air for more than 8 hours, vacuum drying at 105C for more than 8 hours is recommended. Nylon 6 injection molding process parameters Melt temperature: 240-250°C, 250-280°C for reinforced varieties.

Pre-drying: drying at 90°C for 4 hours, except for feeding directly from the charging container; nylon has water absorption and should be stored in a moisture-proof container and a closed hopper; water content exceeding 0.25% will cause molding changes .

Recovery rate: 10% recycled material can be added.

Shrinkage rate: 0.7%-2.0%; or adding 30% glass fiber, the shrinkage rate is 0.3%-0.8%; if the provided temperature exceeds 60ºC, the product should be gradually cooled; gradual cooling can reduce the shrinkage after molding. That is, the product shows better dimensional stability and small internal stress; it is recommended to use the steam method; nylon plastic products can be checked for stress by melting the flux.