Basic Info.

Mould Cavity

Multi Cavity

Plastic Material

ABS

Process Combination Type

Single-Process Mode

Application

Household Appliances, Electronic, Home Use

Runner

Hot Runner

Design Software

UG

Installation

Fixed

Certification

TS16949, CE, ISO

Standard

HASCO

Customized

Customized

Transport Package

Wood or Customized

Specification

38.5x36.7x17.4mm

Trademark

PSM

Origin

China

HS Code

3901100001

Production Capacity

600set/Years

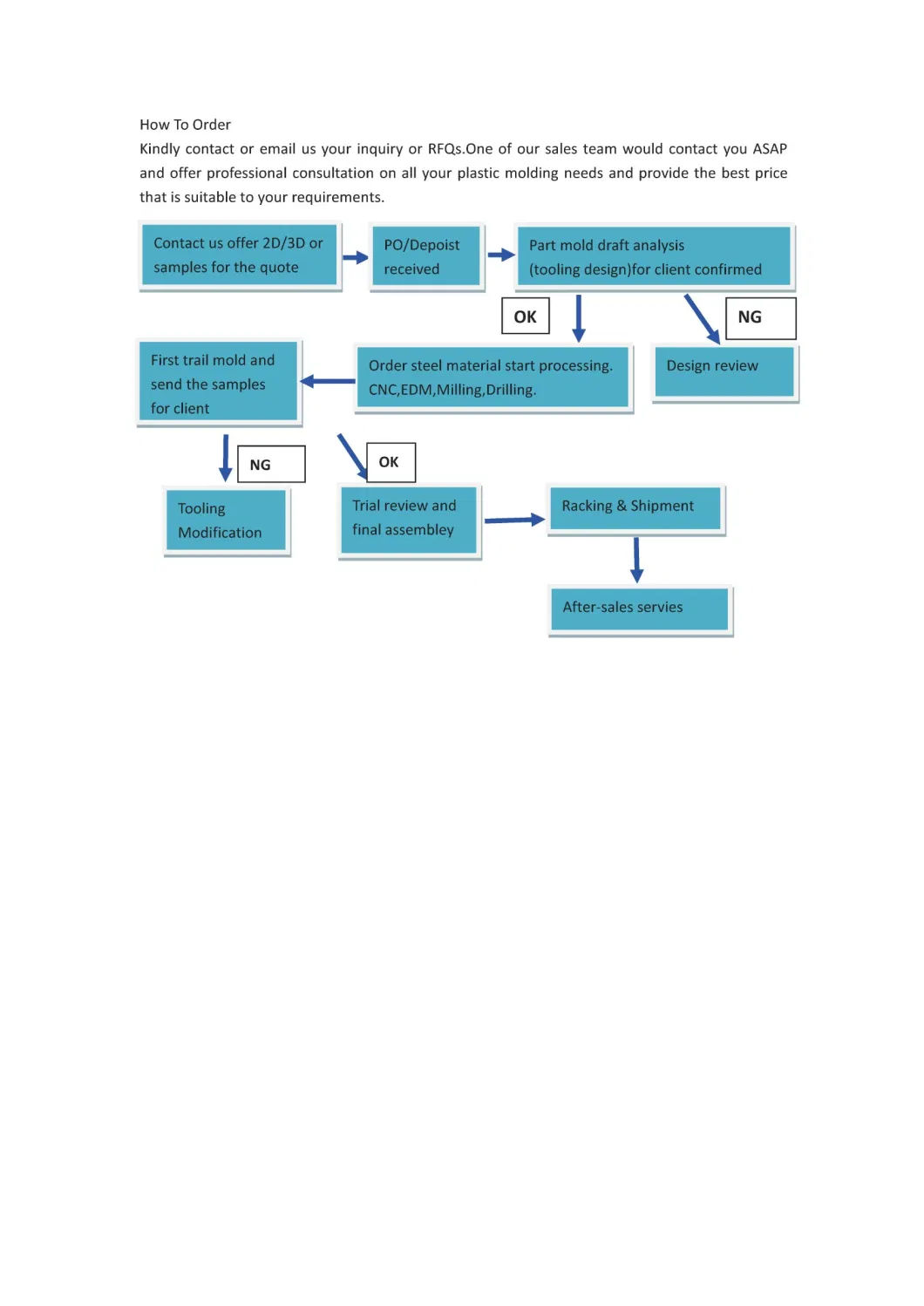

Product Description

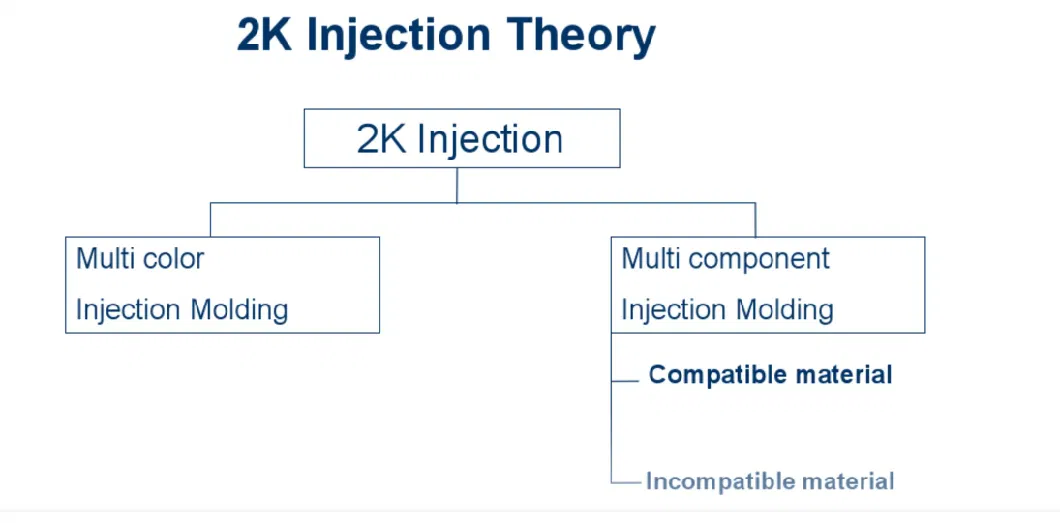

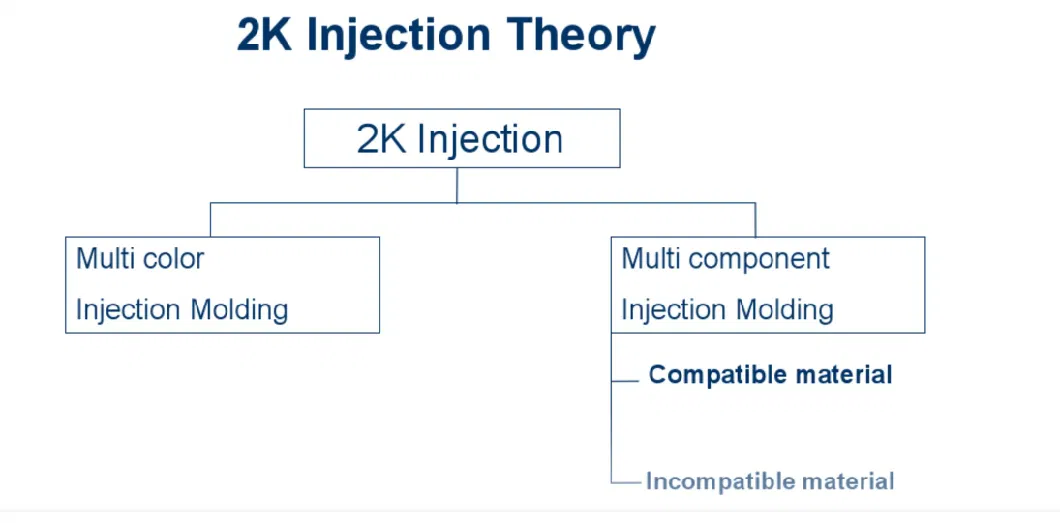

Two-shot Molding Definition

Two-shot Molding,also called over-molding multi-component

or 2K Molding,employs separate injection points

for each material in a sequential process.After initial portion

material or component is molded,the core half of the mold holding

the part is rotated to another,cavity where a second resin is injected

Two-shot Injection Theory

2 Shot Plastic Part

1.Core and cavity:use P20/S13/German 2316

and so on to meet manufactors' need.

2.Mould base:P20/LKM

3.Cavity number design according to your need or

suggest by us according to injection moulding machine

Welcome to contact us for more details of this mould.

More informations about our products are as follow:

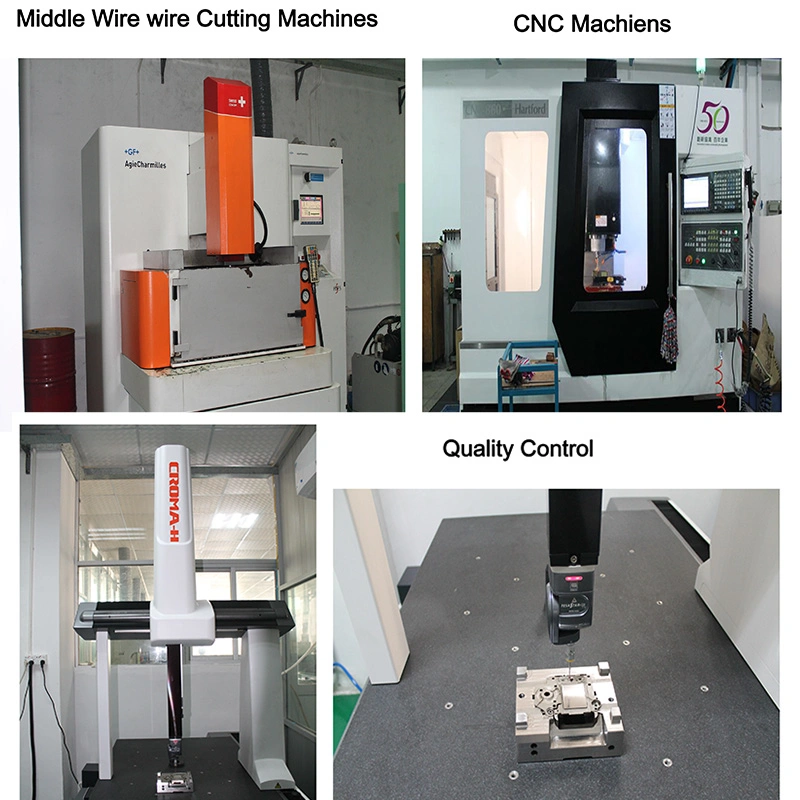

1. Our engineering and mould-making technology includes:

Pro/ENGINEER (3D Modeling)

SolidWorks (3D Modeling)

AutoCAD (2D Modeling)

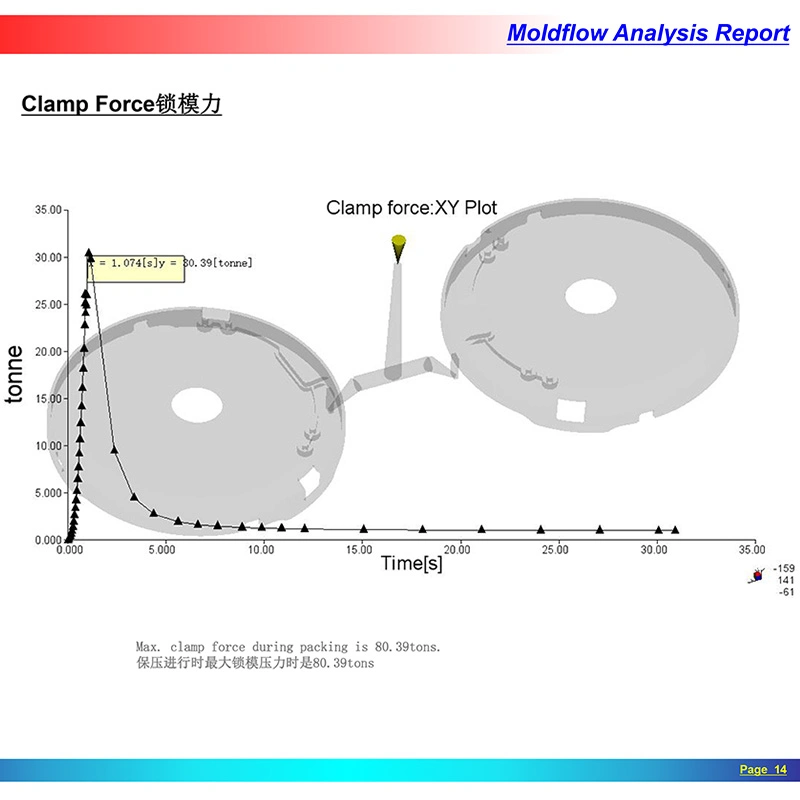

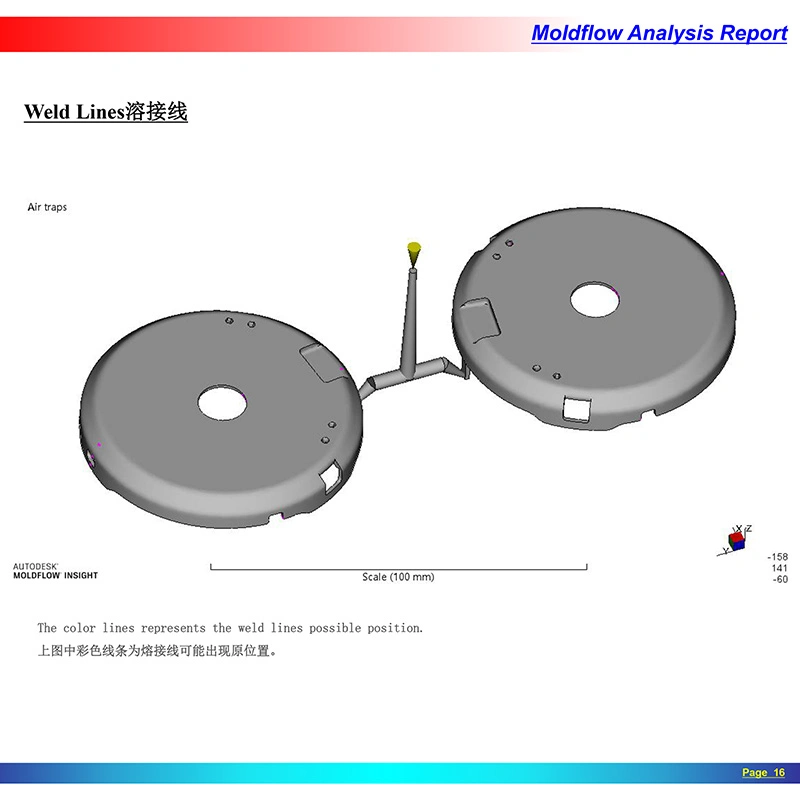

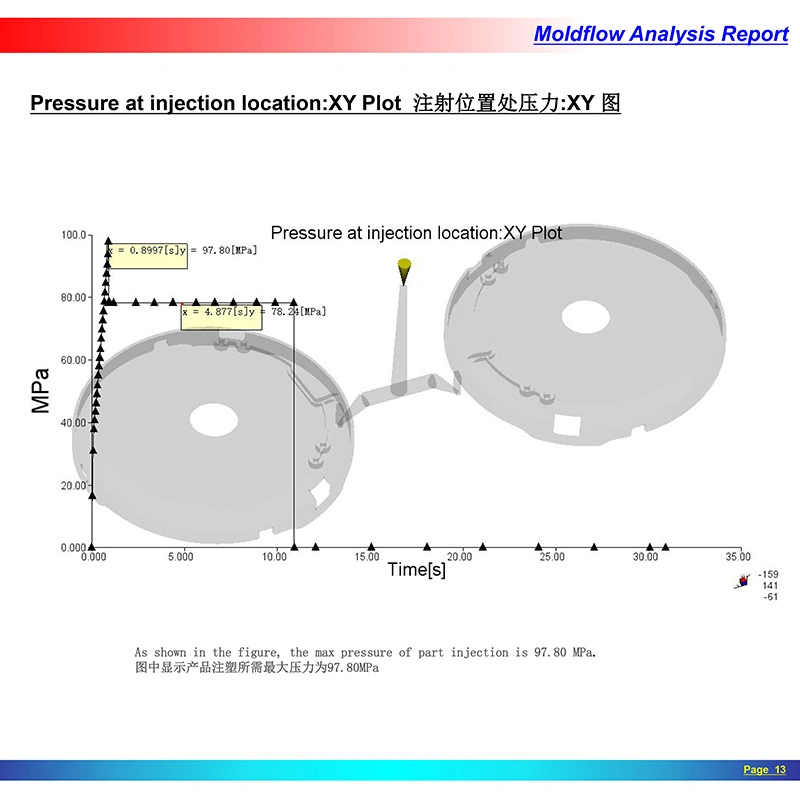

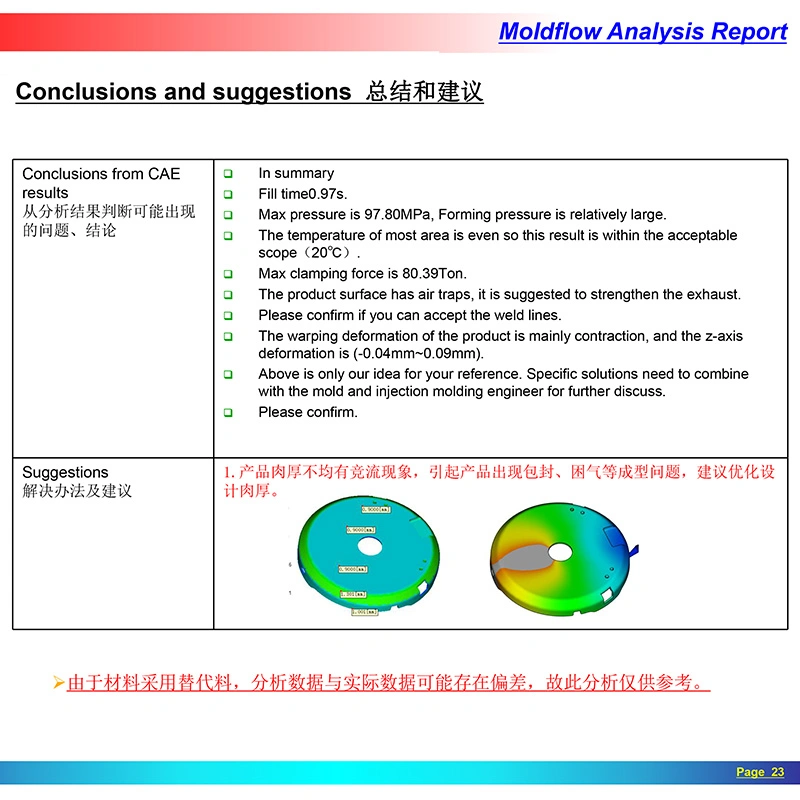

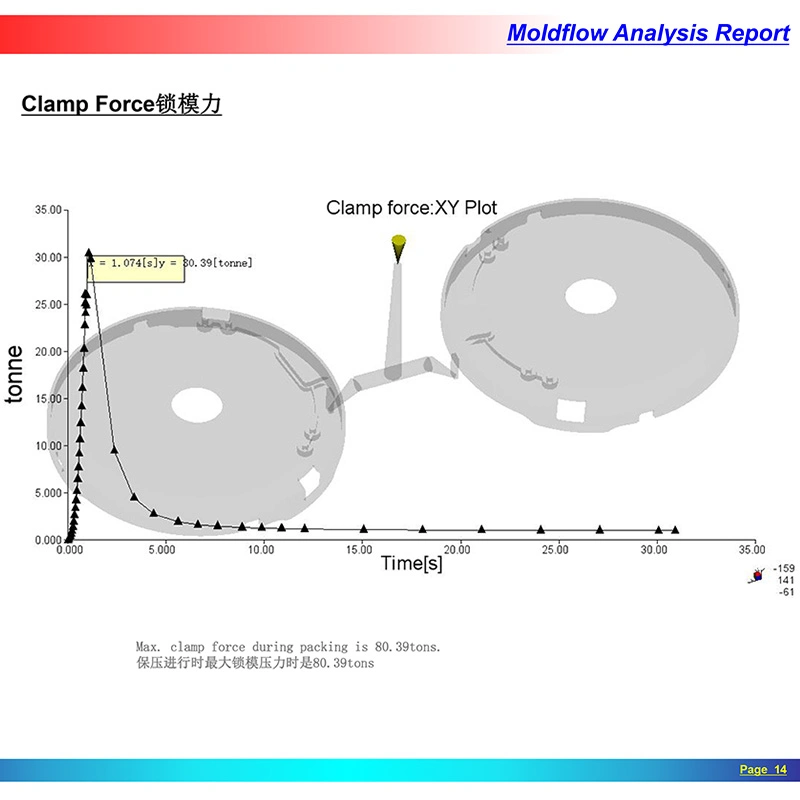

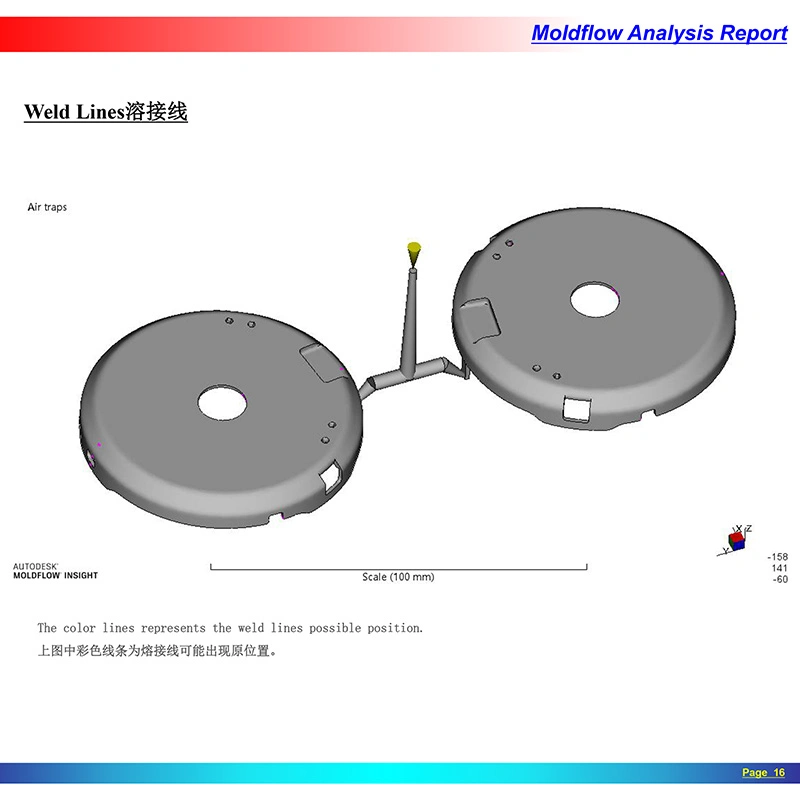

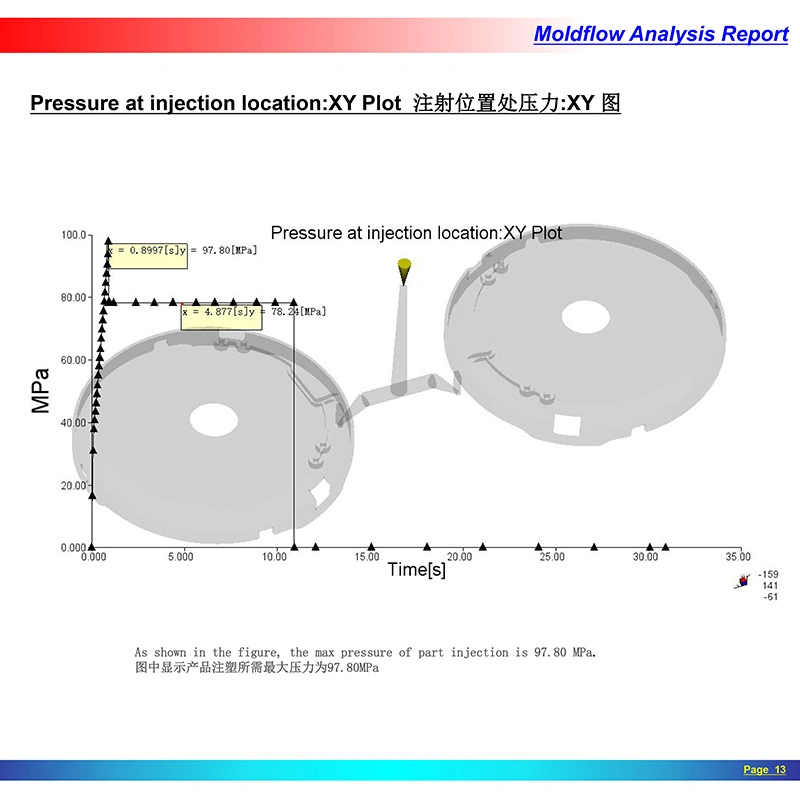

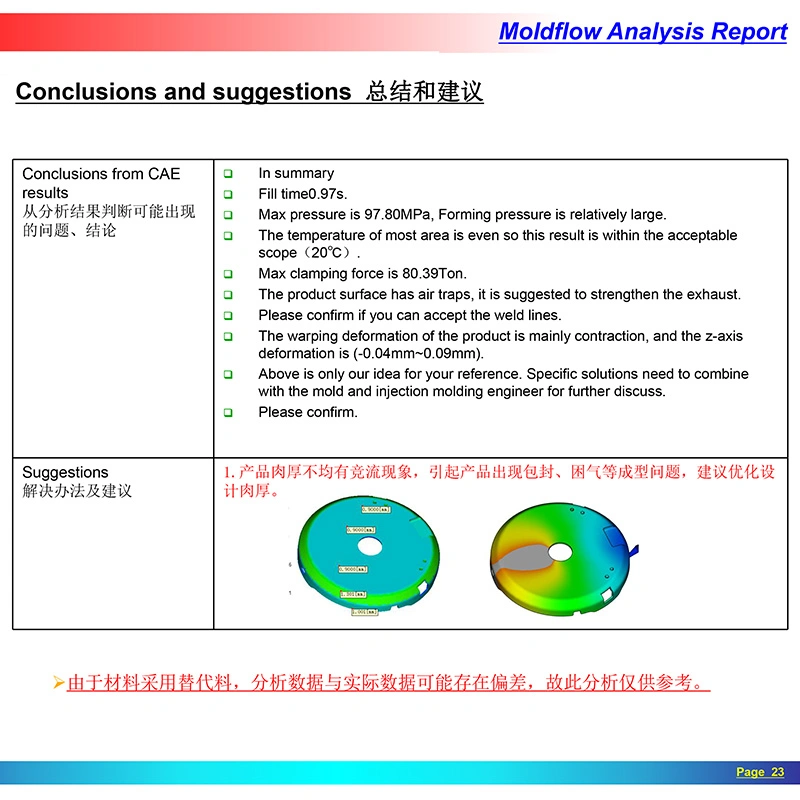

MoldFlow Mold Advisor (Plastic flow/deform simulation)

MasterCAM (CNC Programming)

Unigraphics (CNC Programming)

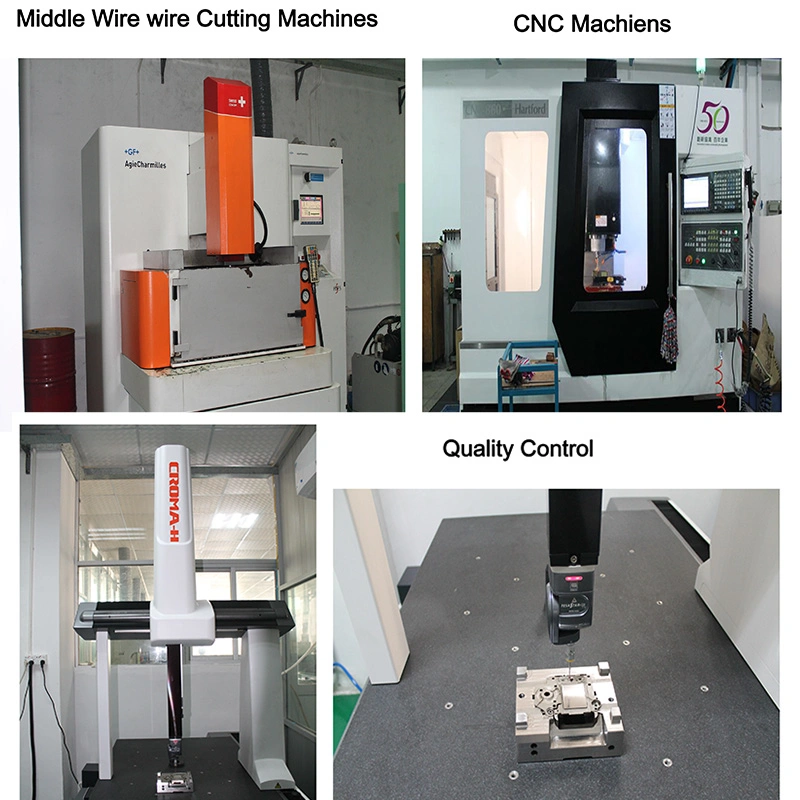

CNC Machining Centers

CNC EDM's (Electro-Discharge Machining)

Wire-Cut Machines.

2. The production can be designed and made according to the 2D or 3D drawings or the samples,which are provided by the customers.

3. We Use many kinds of world-wide applied mould steels,such as 718, 2378, 2083,H13,P20,NAK80,45#,50#,etc.

4. Mould bases and standard components come from

LKM,LYM,DME,etc.

5. We use various plastic materials,such as PP,PE,PU,PC,PVC,ABS,PMMA,etc.

We adhere to the purpose of "creating the best product and providing the superior service" to serve our customers.

Powerfulsky Mould is specialized in Plastic Molding and

Consumer Electronics manufacturing.

Two-shot Molding,also called over-molding multi-component

or 2K Molding,employs separate injection points

for each material in a sequential process.After initial portion

material or component is molded,the core half of the mold holding

the part is rotated to another,cavity where a second resin is injected

Two-shot Injection Theory

2 Shot Plastic Part

1.Core and cavity:use P20/S13/German 2316

and so on to meet manufactors' need.

2.Mould base:P20/LKM

3.Cavity number design according to your need or

suggest by us according to injection moulding machine

Welcome to contact us for more details of this mould.

More informations about our products are as follow:

1. Our engineering and mould-making technology includes:

Pro/ENGINEER (3D Modeling)

SolidWorks (3D Modeling)

AutoCAD (2D Modeling)

MoldFlow Mold Advisor (Plastic flow/deform simulation)

MasterCAM (CNC Programming)

Unigraphics (CNC Programming)

CNC Machining Centers

CNC EDM's (Electro-Discharge Machining)

Wire-Cut Machines.

2. The production can be designed and made according to the 2D or 3D drawings or the samples,which are provided by the customers.

3. We Use many kinds of world-wide applied mould steels,such as 718, 2378, 2083,H13,P20,NAK80,45#,50#,etc.

4. Mould bases and standard components come from

LKM,LYM,DME,etc.

5. We use various plastic materials,such as PP,PE,PU,PC,PVC,ABS,PMMA,etc.

We adhere to the purpose of "creating the best product and providing the superior service" to serve our customers.

Powerfulsky Mould is specialized in Plastic Molding and

Consumer Electronics manufacturing.