- Overview

- Product Description

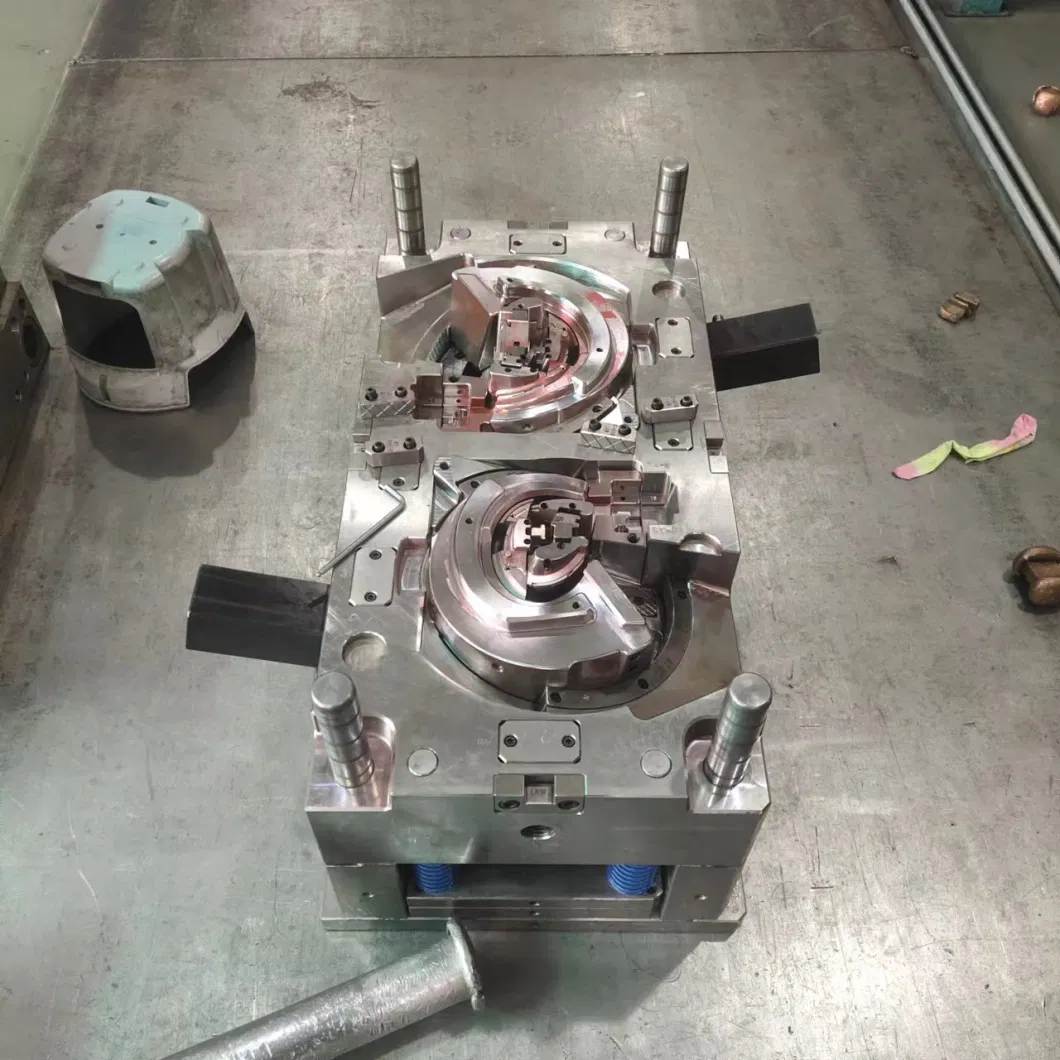

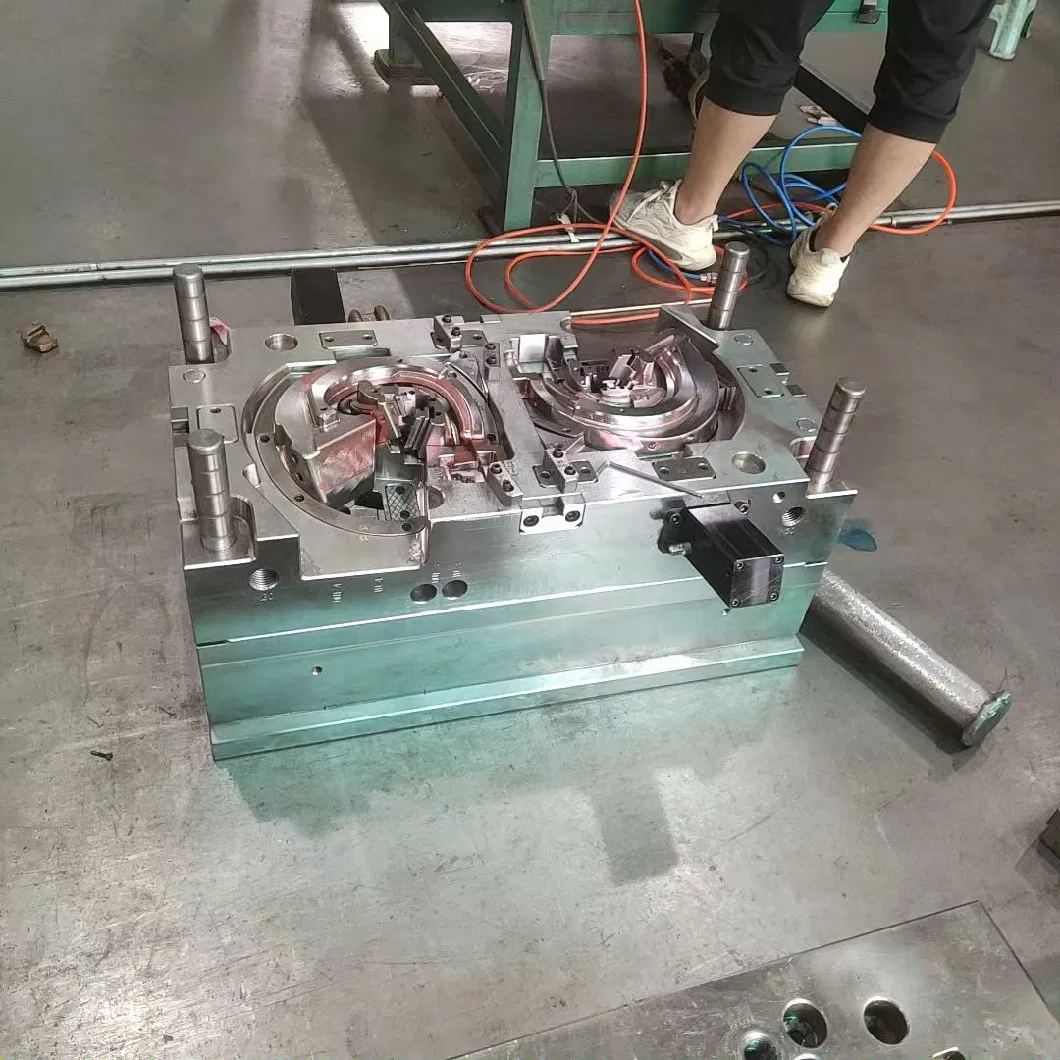

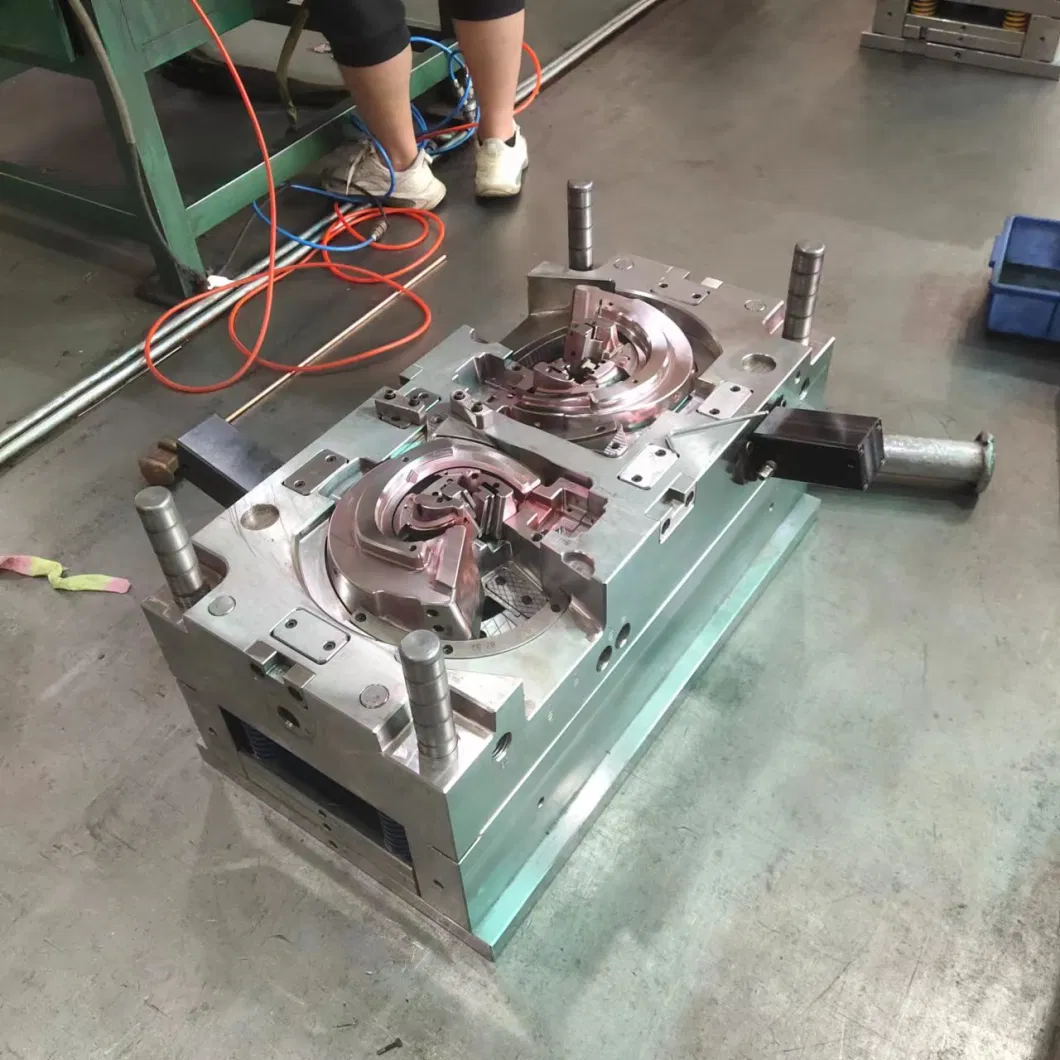

- Detailed Photos

- Other Products

- Quality Control

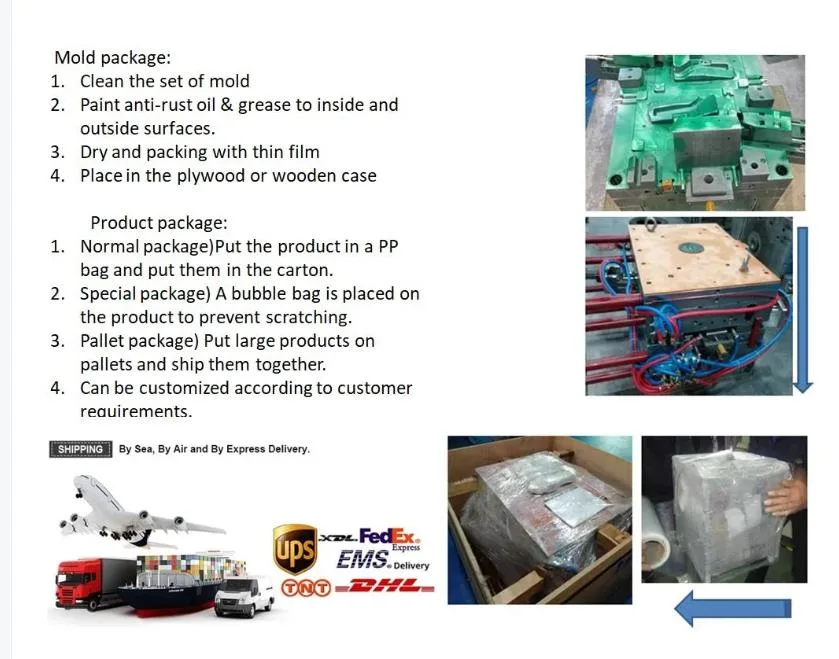

- Packaging & Shipping

- Our Advantages

- Company Profile

- Business Partner

Basic Info.

Packaging & Delivery

Product Description

| Product name | Customized Manufacturer Plastic Injection Molds/ Mould/Tooling For Automobile Parts |

| Products Variety | We design and manufacture plastic injection molds auto parts, home applications, medical products, Household commodities, consumer electronics, mobile phone parts,and accessories, and many other kinds of molds in different fields. |

| Main services | 3D design, Prototypes, Mold design, Mold making, Mold tesing, Low volume/ High volume plastic injection production |

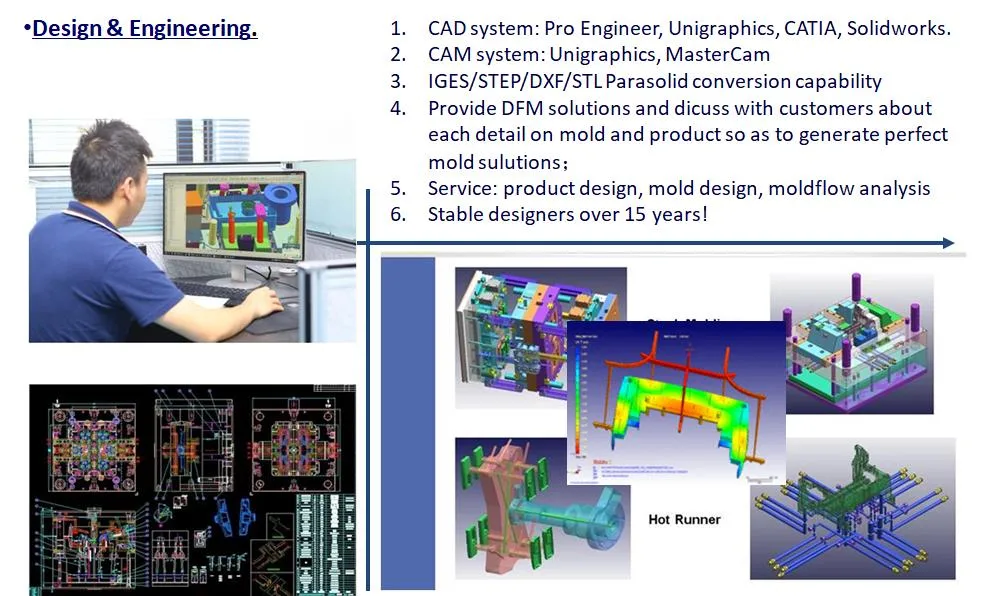

| Design Software | UG,Pro E Solidwork,AutoCAD,Moldflow.... |

| Core&Cavity Material | P20,H718,S136,SKD61,2738,DC53,H13.... |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mould Cavity | Singe or multi cavity |

| Mold strandard parts | DME, HASCO, etc. |

| Runner | Hot runner, Cold runner |

| Hot Runner Brand | Yudo/ Mastip/ HASCO/ DME/ MOLD-MASTER…etc |

| Mold cold runner | Side gate,Sub gate,Pin point Gate... |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

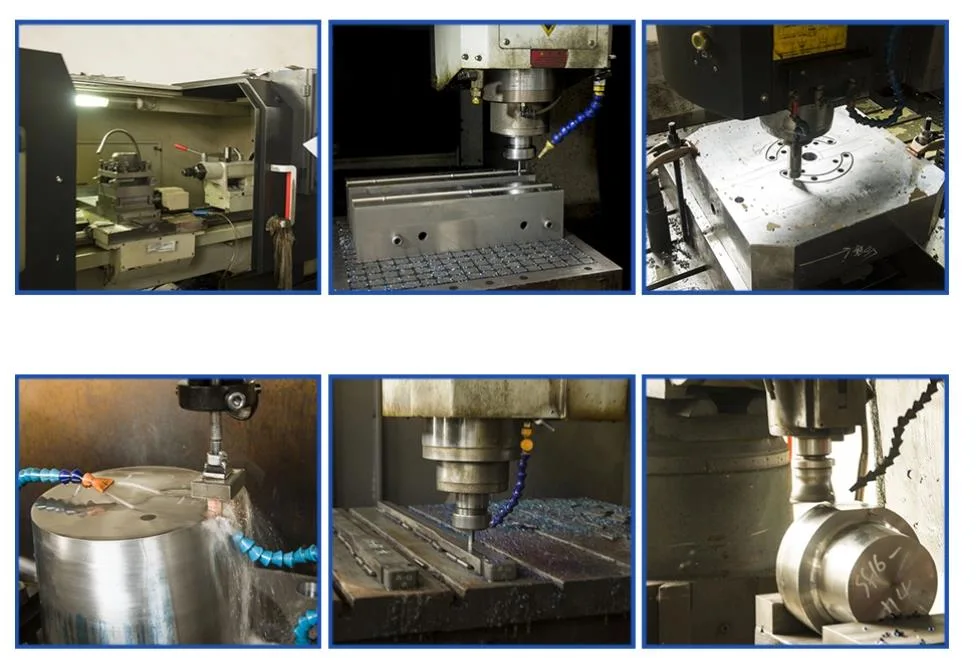

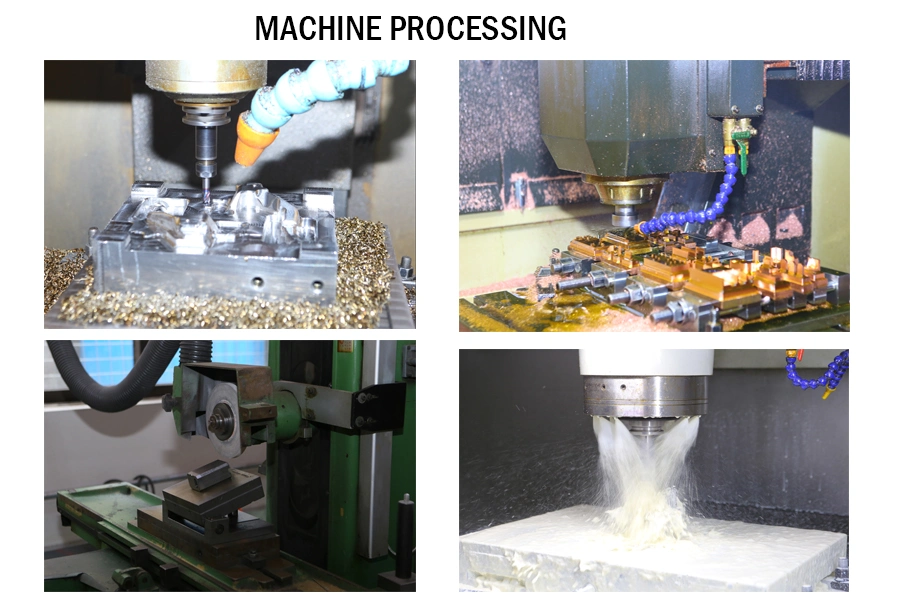

| plastic Injection Machine | 10sets,110T,140T,160T, 200T,260T,320T |

| Plastic Material | PP,Pa6,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| MOQ | 1set for mold ,plastic products as per your request |

| Mold Life | 300000-500000 shots as per customers' requirement |

| Inspection | As customers' requirements |

| Delivery | Air cargo, Sea shipping |

| Lead time | 25-35days for mold,plastic products according to quantity |

How to get a suitable and quality mold?

The engineer consultant will work with you to analyze the mold structure and get your product development cost gudget ASAP.

Mold flow analysis before mold design, process, packaging methods, shipping cost and time.

Why Choose Howe?

Howe provide one-stop service for high volume and technical Plastic Injection Moulding - from product concept design, injection moulding, tooling, plastics manufacture, assembly and packaging on an international basis - we can help you concentrate on your business.

The important thing we can offer you a very competitive price and provide the advanced solution with your porducts design to reduce the mold and producing costs to help your products to be successful.

If you are after a bespoke solution to your high volume plastic injection moulding product requirements then Howe could be the partner for you. If you are in the Medical, Construction, Aerospace, Defence, Nuclear, Automotive, Security, Agriculture or Personal Care industries, then Howe could help.If you are a forward thinking company that wants assistance through every step of the product concept process, then on to the custom plastic injection moulding, we could offer you a solution.

Why choose HOWE MOLD?

1. HOWE MOLD Factory is the leading plastic mould manufacturer in China,based on precise tooling, high technology and top mentality mould design.

2. Design

We are professional for mould design,our engineer designers have more than 10 years experience.

3. Quality

All of our mould steel have certificate with longer mould life,mould produced by advanced equipment,the tolerance can reach +-0.01mm,the molded product have good appearance without any flash and good fit with other products.

4. Price

We always provide competitive price,because of we are manufacturer, we are the source.

5. Service

- Free mould design 2D/3D

- Free sample delivery, 3 times mould test

- Every week update production informations.

- Mould full-life technique support

14. High temperature molding

Dear Customer,

We have more than 12 years experience in making plastic mold& die casting mold.

Our products have TUV ,SGS& ISO9001 Certification.

If you have any demand on our products, contact me free.