- Overview

- Product Parameters

- Product Description

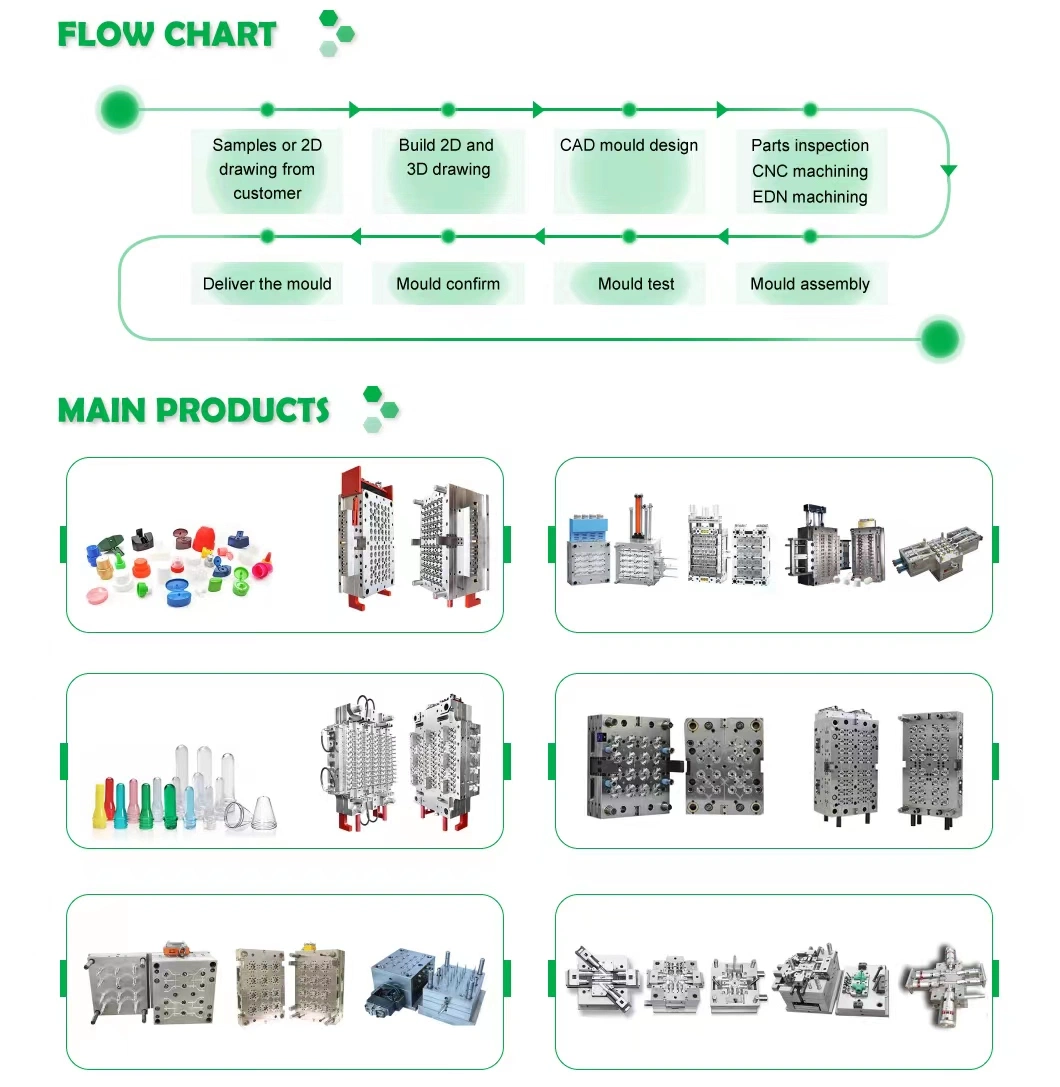

- FLOW CHART

- Company Profile

Basic Info.

Model NO.

Cap Mould

Mould Cavity

Multi Cavity

Plastic Material

PE

Process Combination Type

Single-Process Mode

Application

Household Appliances, Commodity, Home Use, Water Bottle

Runner

Hot Runner

Design Software

UG

Installation

Fixed

Standard

Standard

Customized

Customized

Size

28mm/30mm/32mm/34mm/36mm/40mm

Cavity

2/4/8/12/16/18/20/24/28/32/36/48

Mould Matieral

P20\S136\2316\#45\718/ Copper

Polish

High Polish

Process

Hot/Cold

Gate

Pin Point/Edge Gate

Transport Package

Wooden Package

Specification

SGS

Trademark

Yongsheng

Origin

China

HS Code

8480719090

Production Capacity

500sets/Year

Packaging & Delivery

Package Size

80.00cm * 70.00cm * 60.00cm

Package Gross Weight

800.000kg

Product Description

Custom Multi Cavities Plastic Cap Inject Mould Mineral Water Bottle Cap Moulding

| Cavity | 1-72 |

| Mould base material | P20 , 45# , 4CR13 , .ECT |

| Core&Cavity material | S136,718, P20,2378,2316,4CR13,P20 .ECT |

| Runner | Cold /Hot (LOCAL BRAND,HASCO,YUDO,HUSKY .ETC) |

| Life time | 3,000,000 shots |

| Quick T1 time | 25-40 days |

| Package | wooden case |

| After Sale Service | Any mould problem,we will provide free maintenance service |

ADVANTAGE

1) Saving 10%-30% cost than others.

2) Direct factory price

3) Life:3, 000, 000 time

4) 2D and 3D provided

5) Quick T1 time: 25-40 days

6) More than 15 years experience

1) Saving 10%-30% cost than others.

2) Direct factory price

3) Life:3, 000, 000 time

4) 2D and 3D provided

5) Quick T1 time: 25-40 days

6) More than 15 years experience

MOULD MANUFACTURE PROCESS

Cap Mould : grinding→fly-cutter →CNC Milling→drilling→lathe→boring lathe→electric pulse →fine fly-cutter→polish→electroplate→install

Cap Mould : grinding→fly-cutter →CNC Milling→drilling→lathe→boring lathe→electric pulse →fine fly-cutter→polish→electroplate→install

| 1 | Sample or 2D,3D drawing from customer |

| 2 | Bulid 2D,3D drawing |

| 3 | CAD mould design |

| 4 | Send drawing to customer to confirm |

| 5 | Parts inspection/CNC machining/EDN machining |

| 6 | Mould assembly |

| 7 | Mould test |

| 8 | Send sample to confiom |

| 9 | Dilver the mould |

After many years of efforts and sustained fast developments, we have obtained customers' recognition with our scale, quality and good faith. Now we have got a clear advantage on technologies and equipments levels, quality grades, market share etc. And our core competencies are keeping on being stronger and stronger. It goes without saying that our company will develop steadily, rapidly and healthily. In order to be more professional, solider, stronger and bigger, we insist on perfect quality, good faith and customers first from our foundation, never stopped developing technologies and products.

Now our products are popular in domestic market, and become a famous national brand. In oversea market, they are sold to Americas, Europe, Middle East, Africa and Southeast Asia. We will keep on fast development, strengthening personnel training and introduction, developing technologies, enhancing the capability of independent innovation, accelerating new plastic perform development, improving technology progress and industry upgrade, and carry out "going-out" strategy seriously, take part in the competition actively to open much wider market all over the world.

"YONGSHENG- keeps up with times and makes friends with all over the world"

Q:Are you a factory or trading company?

Q:Are you a factory or trading company? A: Factory.

Q:Can you make the specific molds according to customers?

A:Yes.

Q: How long is your delivery time?

A: Generally it is 45-65 days.

Q: Do you provide samples ?

A: Yes, We will provide samples to our customers after the first molds trial by free.

Q:How to ensure the quality of the product?

A:We have great R & D department and strict quality control department. We will design and manufacture all kinds of molds according to customer's requirements.