- Overview

- Introduction

- Product Details

- Factory Capability

- Our Service

- Packaging & Shipping

- FAQ

- Contact Us

Basic Info.

Product Description

Moldor Plastic has over 15 years of Injection Molding Expertise. Especially in plastic mold & molding manufacturing, with our knowledge we can provide outstanding service to fulfill all your molded part requirements. Our Facility and technical ability will exceed your expectations on service, quality and value.

We currently have a wide variety of Molding equipment ranging from 50T to 1000T for Plastic Injection Over Molding , including Horizontal& Vertical versions.

Our injection moulds and injection moulded plastic parts are widely used in electronics, household appliances, medical devices, sporting goods, promotion gifts fields and others.

| Product Name | Plastic injection mold for plastic parts |

| Mold Shaping | Customized Plastic Injection Mold |

| Nos of Cavity | Single or multi as per customers' requierment |

| Design Software | UG, PROE, CAD, etc. |

| Plastic Material | PP, PC, PS, POM, PE, ABS, etc. as per customers' requierment |

| Mold Life | 300000 - 1000000 shots |

| Runner | Cold or Hot |

| Delivery Time | 15 - 30 days |

| Payment Terms | T/T, Paypal, Money Gram or others |

| Packaging | Wooden case for molds, Cartons for plastic products. |

Customize your own moulds in MOLDOR PLASTIC !

* In-house mold design and building capabilities to Improve work efficiency.

* Factory price makes your cost transparent.

* NDA agreement can be signed to protect customers' idea and design.

* Professional sales team. Good communication skills and after-service.

* Professional design team, mold maker engineer. OEM/ODM service.

* Professional QC and R&D teams to assure high quality.

* In time response to letters and emails.

* On time delivery.

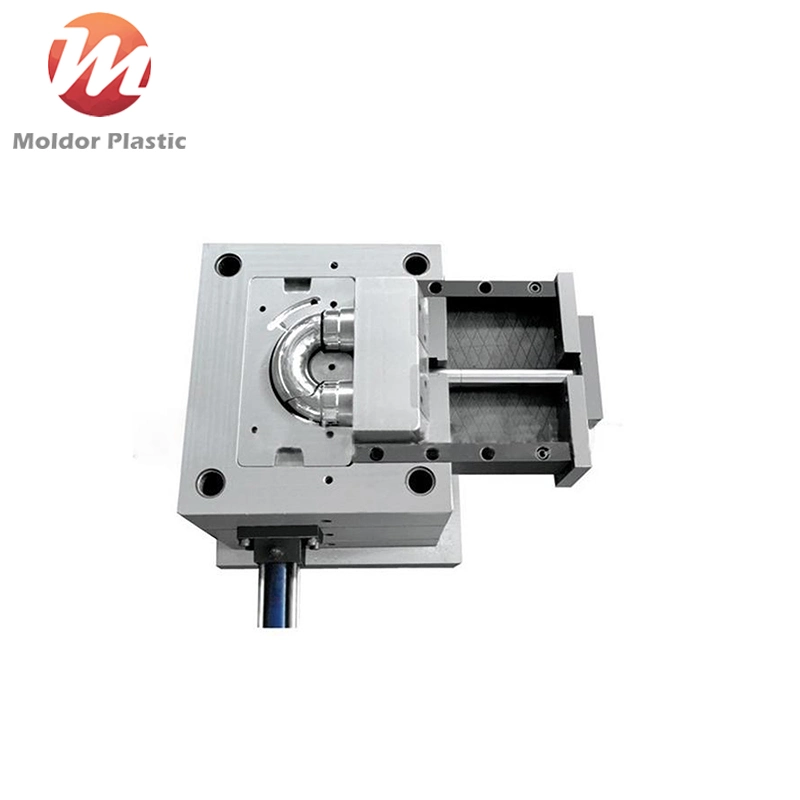

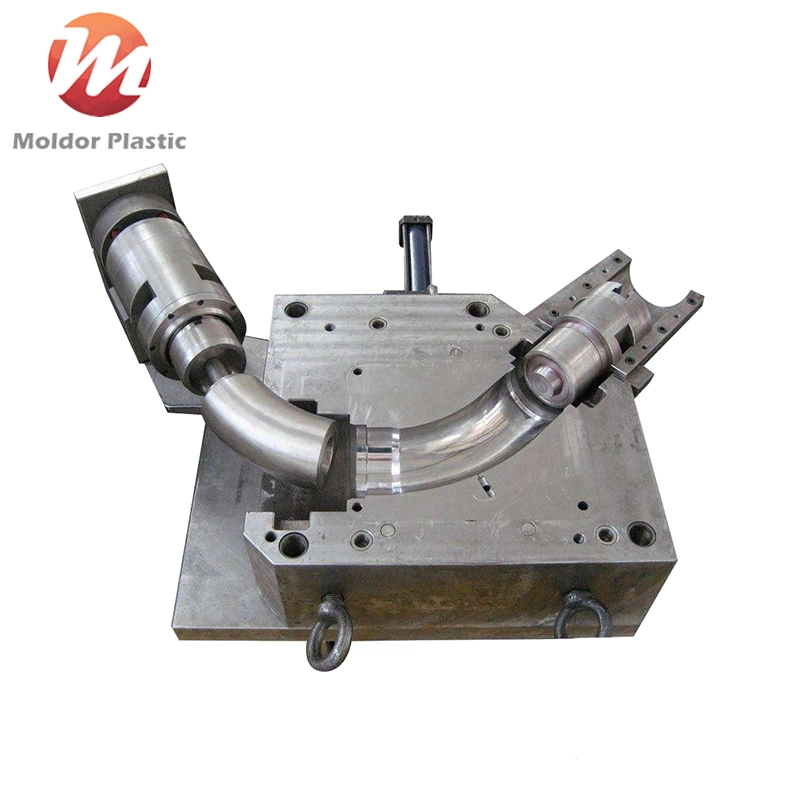

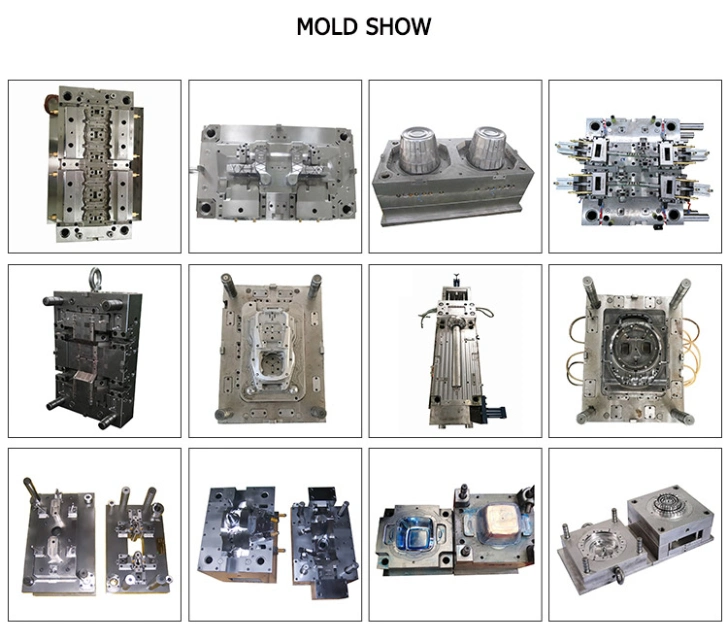

Our tooling work is able to make different size of molds with single cavity or multi cavities. With your product data, our engineer can provide you the feasible project with low price and high quality. Below shows our manufacturing apability:

1. Maximum mold size 2500mm*2000mm*1500mm

2. Maximum mold weight: 15 ton

3. The highest machining precision: ± 0.005mm

4. The highest injection precision: ± 0.03mm

5. Experience of high precision molds and custom injection molding for healthcare and high-grade appearance parts

6. The yearly production capacity of molds is over 350 sets

7. Delivery time for each mold is from 25-45 days, depending its complexity

8. We equip our own high precision CNC machines, EDMs, Wire cut machines, mirror EDM, three-coordinates measuring machine to ensure the quality of both mold and injection parts.

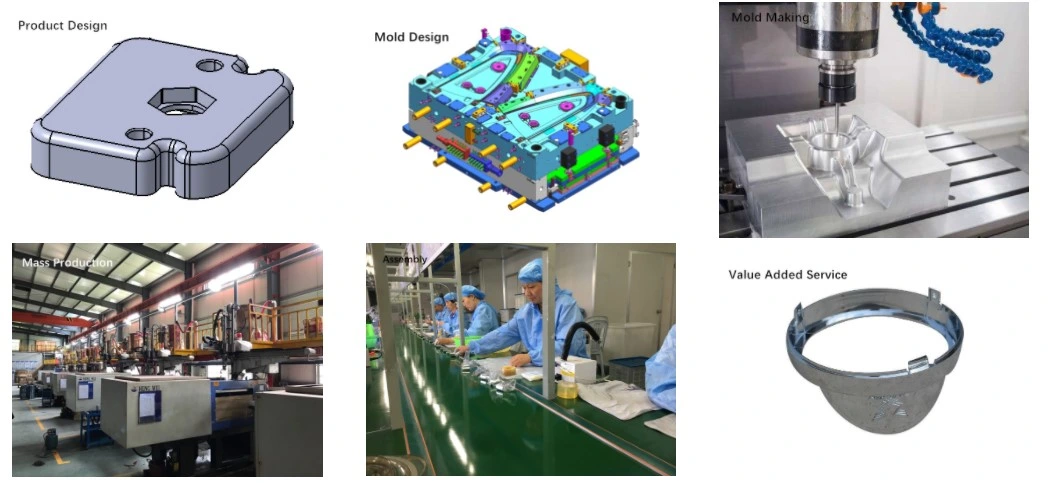

Step 1: Product Design: We provide product design service as customers' request.

Step 2: Mold Design: We communicate & exchange the detail information with our customers to make a good mold design.

Step 3: Mold Making: Manufacturing in-house, we send the mold processing photos and videos to customers.

Step 4: Mass Production: We start plastic injection parts production after customers confirm samples.

Step 5: Assembly: We can supply assembly service as customers' requests.

Step 6: Value added Service: Available, such as screen printing, plating, custom packaging and etc.

Q1:Are you a trading company or factory?

A1:We are factory.

Q2:What type of information is required for quoting a molding project?

A2:Please send your drawings or sample to us.

Q3:How long do you take to build a mold?

A3:The production timeline depends on your specific needs, normally the lead time is 25-45days.

Q4:How small or large of a plastic part will you produce?

A4:Our machine capabilities cover a range from 60-ton to 500-ton clamping forces.

Q5:What kind of steel do you use for plastic moldings?

A5:We can use any type of steel appointed by customer or popular in the market.Such as P20,718,8407,NAK80,H13,S136,

DIN 1.2738,DIN 1.2344,etc.

Q6:What types of materials can be molded by your injection products?

A6:Polystyrene,ABS,PET,TPR,TPU,PVC,Nylon,Acetal,Polypropylene,Polyethylene, Polycarbonates and etc.

Q7:Do you offer secondary service such as assembly, packaging or painting?

A7:Yes,such as assembly, painting, tapping, ultrasonic welding, trimming, sorting, customized packaging and etc.

Q8:If I have an existing tooling, could you use it to mold my project?

A8:Most certainly, if existing tooling is available, we can use them.

Q9:Can you mold around inserts or metal components?

A9:We can do insert molding with just about any metal and non-metal components.