Basic Info.

Model NO.

200tons

Transport Package

Standard Export Package

Specification

XLB-500x500

Trademark

JUNFAN

Origin

Made in China

HS Code

84778000

Production Capacity

200sets/Year

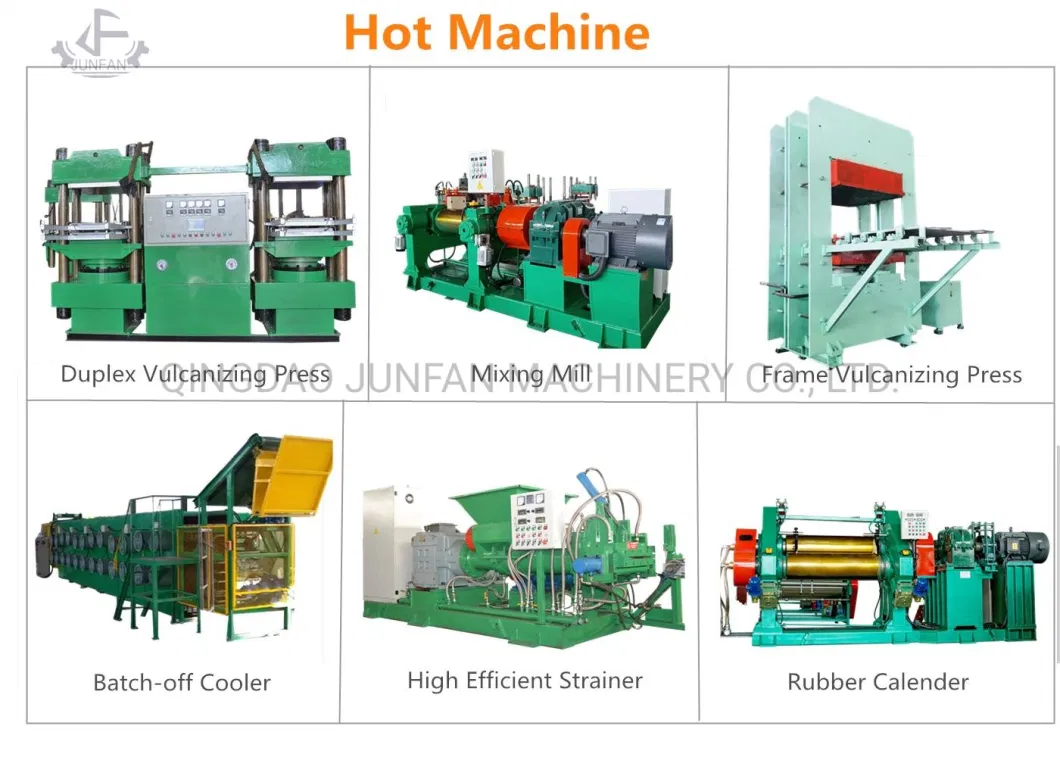

Product Description

Automatic Series Rubber Injection Molding Vulcanizing Machine\

Application:

Rubber vulcanizing press applies to all kinds of rubber (natural rubber, EPDM rubber, NBR rubber, synthetic rubber, silicone rubber ext. ) vulcanizing and compression molding.

rubber vulcanizing press can be used to make O ring, sealing parts, oil seal, auto parts, rubber crash pad, rubber air spring, key board, medical rubber parts, rubber bottle stopper, silicone wrist band, water-stop tape, bridge support/bridge bearings, rubber cable, electronics insulators etc..

All our machines can be customized according to your requirements.

Vulcanizing Press Describe

1.suitable for producing insulator, arrester, bushing, cable joint and all kinds of rubber mold products.

2.Provide big work table

3.All key hydraulic and seal components are imported from Europe, USA or JAPAN, ensuring oil pump can do any actions without impact

4.Save 25-50% motor energy cost

5.Use Germany electronic ruler to measure the injection, ensure the precision

6.Three sections of injection pressure, flux and pressure holding satisfy any products' technological requirements

7.Siemens PLC controller and touch screen make it easy to set up, view and save Technological parameters. It can also supervise the whole producing, auto diagnose inner fault And give an alarm

8.Protect with safe light curtain

9.Precisely fix mold in and out position

10.Control material temperature, Temperature control precision is between ±1 degree

11.300 sets of mould data memory.

rubber vulcanizing press can be used to make O ring, sealing parts, oil seal, auto parts, rubber crash pad, rubber air spring, key board, medical rubber parts, rubber bottle stopper, silicone wrist band, water-stop tape, bridge support/bridge bearings, rubber cable, electronics insulators etc..

All our machines can be customized according to your requirements.

Vulcanizing Press Describe

1.suitable for producing insulator, arrester, bushing, cable joint and all kinds of rubber mold products.

2.Provide big work table

3.All key hydraulic and seal components are imported from Europe, USA or JAPAN, ensuring oil pump can do any actions without impact

4.Save 25-50% motor energy cost

5.Use Germany electronic ruler to measure the injection, ensure the precision

6.Three sections of injection pressure, flux and pressure holding satisfy any products' technological requirements

7.Siemens PLC controller and touch screen make it easy to set up, view and save Technological parameters. It can also supervise the whole producing, auto diagnose inner fault And give an alarm

8.Protect with safe light curtain

9.Precisely fix mold in and out position

10.Control material temperature, Temperature control precision is between ±1 degree

11.300 sets of mould data memory.

>>MAIN TECHNICAL SPECIFICATION

| Type/Clamping force(ton) | 100Ton | 200Ton | 300Ton | 400Ton | 500Ton | 600Ton | 800Ton |

Max. stroke(mm) | 380 | 480 | 550 | 550 | 600 | 600 | 700 |

Heating plate size(mm) | 400x400 | 494x508 | 575x600 | 700x700 | 800x800 | 900x900 | 1100x1100 |

Injection volume(cc) | 900 | 1500 | 3000 | 4000 | 5000 | 8000 | 10000 |

| Max.Injection pressure(kgs/cm2) | 2000 | 2000 | 2000 | 1800 | 1810 | 1870 | 1890 |

| Max.Injection rate(CC/s) | 45 | 50 | 70 | 97 | 111 | 148 | 186 |

Horse power(hp) | 15 | 15 | 20 | 25 | 30 | 40 | 50 |

Type of mold opening | Up/Down-In/Out-2RT/3RT/4RT | ||||||

Total power(kw) | 21 | 27 | 33 | 43 | 52 | 68 | 91 |

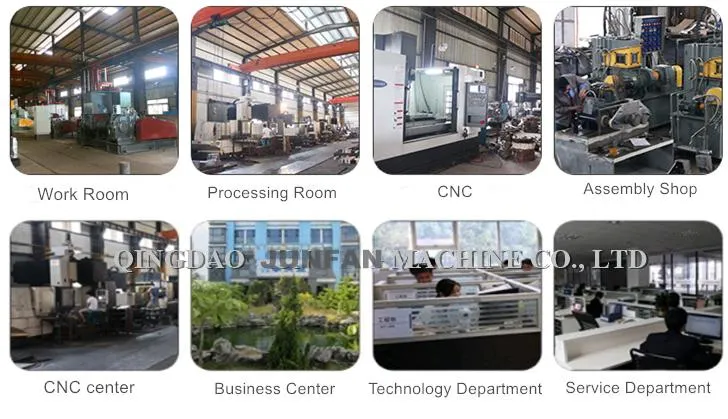

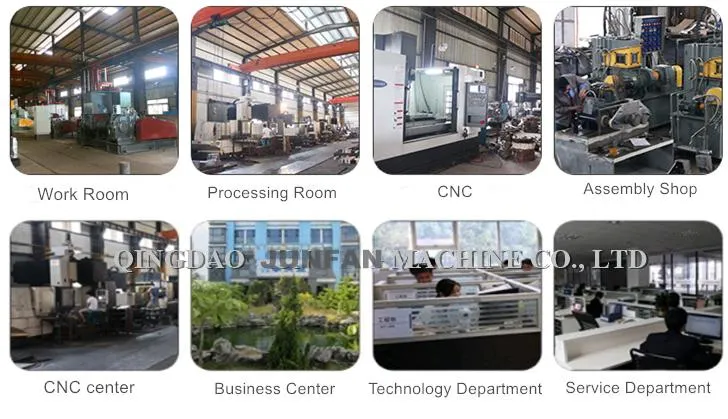

Company Advantage

1. CE, ISO9001, TUV Certificate.

2.100% meet your requirement.

3. Sell to about 126 countries on 6 continents.

4. One year quality guarantee and long-term technical support;

5. With more than 40 years of history in the rubber machine industry.

2.100% meet your requirement.

3. Sell to about 126 countries on 6 continents.

4. One year quality guarantee and long-term technical support;

5. With more than 40 years of history in the rubber machine industry.

>>FAQ

1. Delivery time of the rubber machines?

This is specially designed machine according to your specific requirement.

From engineer designing to production completion, it needs about 25 to 35 days.

2. What does your factory do regarding quality control?

We pay much more importance to quality control from the very beginning to the end of production.

Every machine will be fully assembled and carefully tested before shipment.

3. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand components to keep our machine in perfect working condition.

4. Are you able to give installation and commissioning overseas? How long time will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation.

Small machine usually takes within 2~3 days.

Big plant usually takes about 30 days.

5.How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order.

The core of our company culture is innovation,quality,integrity and efficiency. Also we have had many good cooperation with world famous rubber production manufacturers. If you come to our factory, we can show you're the user around us.

6.How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name of airport is Qingdao liuting airport.

We will pick up you at the airport.